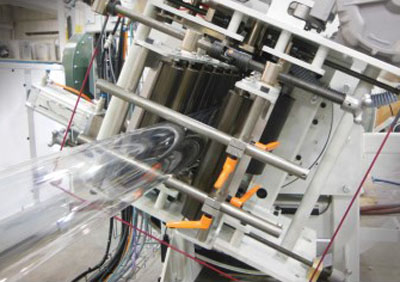

Zahoransky AG, a Germany-based plastics processing machine supplier, has introduced its new Z.LYNX3 fully automated machine for

production of nylon and wire brushes on August 30.

According to Zahoransky, the Z.LYNX3 guarantees a consistent product quality of twisted brushes with an end capped on one side or eyelets, which can be made into a diameter from 6-40mm. Optionally, non-rounded eyelets can also be produced. The full servo control offers the operators process stability including screw-in monitoring, wire feeding, wire straightening, wire shaping and wire cutting.

The program changes of the decisive processing steps are easy, safe and quick. The CNC-controlled cutter device with HSS trimmer provides for an automated finish. The electronically secured protective housing of the Z.LYNX3 is also safe, said Zahoransky.

The Z.LYNX3 is equipped with a screw-in machine that boasts an automatic feed of the handle wire. Coming from a wire coil, the wire is advanced at respective length via the servo drive, cut, and bent by the servo-controlled bending plate and the bending roll. The screw-in gripper removes the bent wire from the bending plate. A strip of material is pushed between the bent wire and turned between the screw-in rolls. A CNC controlled trimming device with HSS trimmer cuts the brushes during the screw-in process and thus provides for a highly precise contour cut. The trimming device then cuts the brushes at the desired length. Ejection of the ready brushes takes place via a conveyor belt.

As stated, he Z.LYNX3 provides for the manufacturing of wire tufting or nylon filaments via a spool or a material preparation unit for material lengths between 30-130mm. The ZMI3 touch screen control enhances operating smoothness and provides for a clearly arranged production data acquisition and recipe management.

Zahofansky said that the unit costs of brushes manufactured with the Z.LYNX3 are comparable to costs of manual or semi-automated systems.

Source : www.adsalecprj.com