The Austria-based injection moulding machine manufacturer’s MES is called Temi+. It contains modules for intelligent production planning, monitoring, data storage, and it seamlessly interacts with production cells enabled by Wittmann 4.0, the company’s Industry 4.0 technology.

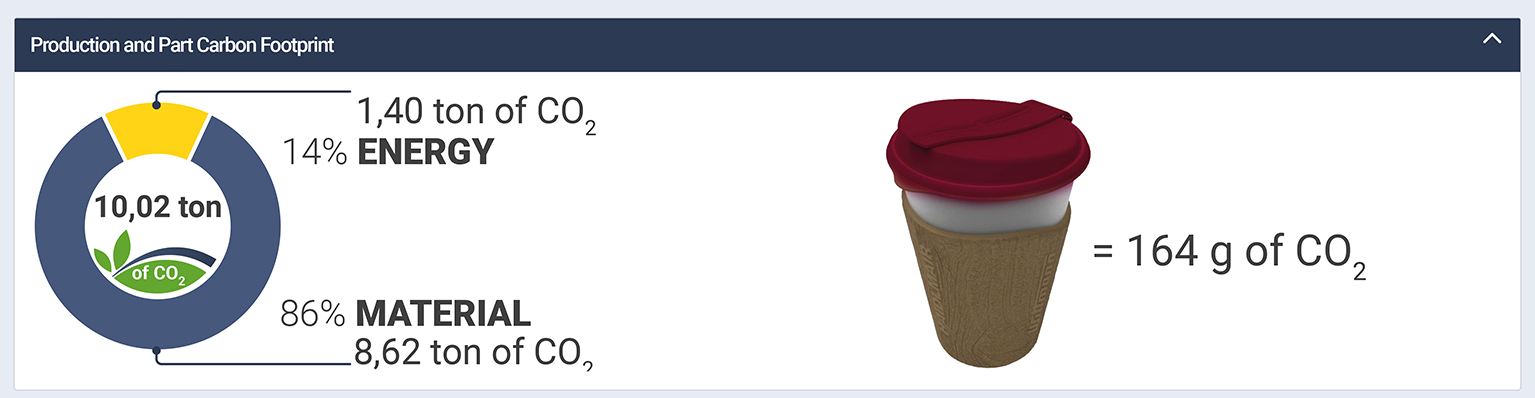

Calculating the product carbon footprint is complex as it includes emissions from the entire life cycle of a product, from raw material production to end of life.

The values for the CO2 footprint of the raw materials are pre-populated into the MES according to the information provided by the material manufacturer. The energy consumption of the production cell is automatically measured by the MES or by using iMAGOxt software, an energy consumption programme developed by Wittmann.

The CO2 emissions resulting from energy consumption thus depend on the carbon intensity of the energy source. Production locations with a renewables-rich electricity grid, or with renewable self-consumption, have lower emissions.

In Germany, for example, given the current electricity mix the factor is 0.354 g CO2 per Wh. This value is stored in the MES or shared from the customer’s Enterprise Resource Planning (EPR) so that the system can automatically calculate the CO2 footprint of the production cell.

Unlike other MES software, the Temi+ package works not only with injection moulding machines but also with auxiliary equipment and robots. It has been developed with a flexible architecture for integrating different devices possibly already present in the factory and for reaching all the injection moulding machines inside the production departments.

Wittmann started integrating the software in its portfolio in 2018 when it formed a joint venture with Ice Flex, an Italian supplier of MES solutions that developed Temi.

Source: sustainableplastics.com