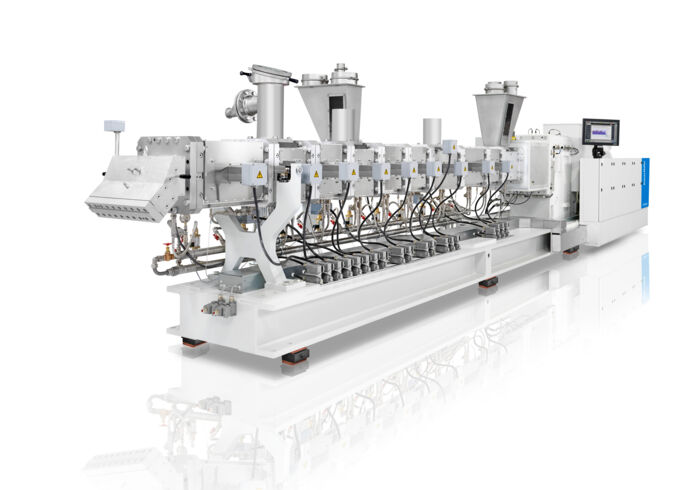

A new series of “wet-grip” thermoplastic elastomer (TPE) compounds for injection molding promises to add to the enormous popularity of

soft-touch features in consumer products by retaining a non-slip surface and secure grip even when wet, it was announced today by Teknor Apex Company, which will introduce the TPEs at NPE2012 (Booth 58038).

Monprene® Wet Grip Series styrenic block copolymer compounds minimize or eliminate a problem encountered with many standard TPEs in soft-touch applications like grips, handles, knobs, and cushions. These products often become slippery and hard to handle when wet from rain, humidity, sweat, dishwater, or other commonly encountered substances. Unlike the standard TPEs, the new Monprene products retain their rubber-like traction when wet, while providing the same elasticity and other key mechanical properties. They are available in hardnesses from 10 to 45 Shore A and can be applied onto a variety of substrates by means of two-shot, coinjection, or insert molding.

“Teknor Apex has spent more than a year perfecting Monprene Wet Grip Series TPEs so that manufacturers of housewares, appliances, personal care items, tools, and sporting goods are able to make their products easier and safer to handle,” said Brian Mulvany, senior consumer market manager. “The proprietary wet-grip chemistry that we have developed addresses everyday situations in the real world, where workers must handle tools, cooks use utensils, and golfers grip clubs regardless of surface conditions.”

In tests measuring the coefficient of friction of a standard styrenic TPE with a Monprene wet-grip grade, the new compound exhibited a coefficient that was 25% greater when surfaces were wet with plain water and 175% greater in the case of soapy water (see bar graph).

Soft-touch components that are potential applications for the new Monprene compounds include those in shaving razors, toothbrushes, writing instruments, paint brushes, hair brushes, hair dryers, hand tools, kitchen appliances, cooking utensils, vacuum cleaners, mops, rakes, shovels, scissors, and sporting equipment.

The Thermoplastic Elastomer Division of Teknor Apex Company is the most diversified manufacturer of TPEs, offering broad product families based on six generically distinct polyolefin, styrenic, and vulcanizate chemistries. Headquartered in Pawtucket, Rhode Island, U.S.A., the division compounds TPEs at eight locations in the U.S., Europe, and Asia and is an international supplier to the appliance, automotive, construction, medical-device, wire and cable, and other consumer and industrial product industries. Other plastics businesses of Teknor Apex include the Bioplastics, Nylon, Specialty Compounding, and Vinyl Divisions and Teknor Color Company. Visit www.teknorapex.com.