LPKF’s PowerWeld3D 8000 utilizes the new “wobbling” process to join components and handle height differences.

A laser welder, which is based on a brand new technology called “wobbling”, has been designed to enable the joining of increasingly lighter-weight plastic automotive large components of up to 100 cm (3.28 ft) x 70 cm (2.3 ft).

A laser welder, which is based on a brand new technology called “wobbling”, has been designed to enable the joining of increasingly lighter-weight plastic automotive large components of up to 100 cm (3.28 ft) x 70 cm (2.3 ft).

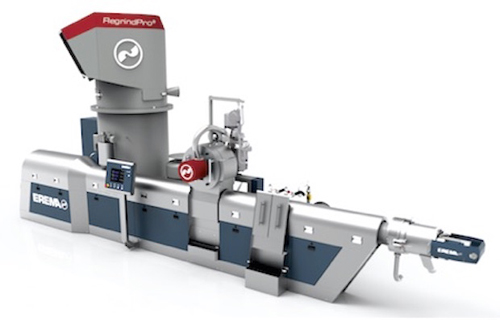

To be showcased at K 2016 and made available in first quarter 2017 by LPKF (U.S. office in Tualatin, Ore.), the PowerWeld3D 8000 laser system reportedly combines integrated melt travel monitoring and very short process times, extending the range of transmission laser welding.

“Wobbling”, is a process in which the laser beam moves with a small amplitude transverse to the weld path. Height differences that could otherwise lead to altered seam widths can be automatically compensated by adjusting the amplitude.

In this quasi-simultaneous process the weld is tracked several times over, creating homogeneous temperature distribution. Analysis of the setting path and welding time generates reliable data about weld quality. The new system is said to be ideally suited for such large components as interior automotive lights and lamps.

Website:www.ptonline.com