Stunning architecturalapplications shining a light on the potential of anodizing aluminum

Clariant has been providing dyes and colorants for finishing anodized aluminium for more than half

a century and a unique three-way partnership is highlighting the design possibilities using this

special process.

Almost one-hundred years ago aluminum revolutionized the world with the discovery of new

manufacturing processes and strong alloys that were lighter than steel. Today, its properties make

aluminum attractive for many industries including transportation, electrical and packaging,

architecture, and food. As it’s recyclable it also has environmental and economic advantages.

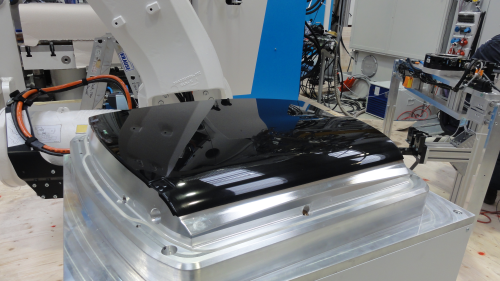

Aluminum creates a sophisticated look that can transform an application and, in many

applications, including architecture, it can be anodized – a process that protects against corrosion,

enhances aesthetics, resists scratching and is very durable.

Just over a decade ago the Belarussian aluminum floor coverings company KTM-2000 decided to

invest seriously in the construction of its own anodizing line and, in addition to its existing

business, it added the anodizing of aluminum façade claddings to its catalogue. The rest, as they

say, is history.

“In 2014 I met Clariant and its distributor for its anodized aluminum colors, Omya. After the

inspiration of these meetings, we decided that Clariant’s dyes could significantly expand KTM2000’s capabilities, and the three-way partnership would help our business gain the experience to

make a unique offer on the market,” said Taras Gvozdkov, CEO of KTM-2000. Clariant’s portfolio

for aluminum finishing for Europe, North Africa and the Middle East is available through its

exclusive distributor Omya (Schweiz) AG.

In quick succession KTM-2000 was commissioned to produce the façade of the Office of the 3rd

line of the Minsk Metro and the façade of the Primakov school in a region of Moscow.

“Clariant and Omya helped KTM-2000 through these projects in a collaborative way, overcoming

challenges through technical consulting and on-site trainings and workshops. The results spoke for

themselves with finishes that display excellent light and weather fastness – unique in the industry,

scratch resistance, corrosion stability, surface hardness, and heavy-metal free formulation,”

explained Andreas van Baerle, Head of Sales Aluminium Finishing EMEA at Omya.

These led to the KTM-2000’s most significant project to date, the Palace of Rhythmic Gymnastics

in Minsk where experience acquired from earlier commissions proved critical. “We had to complete

the project in a very short time and finish a 10’000 square meter facade with 12 different color

shades. It was a real challenge, but we developed 18 new work methods and new technological

approaches to color anodizing. As a result, we completed the project on time and in just 70 days,”

explained Gvozdkov.

Clariant’s palette of high-quality colorants for aluminum finishing is one of the broadest in the

industry, with tailor-made solutions focused on improved sustainability and energy efficiency. The

range of dyes and aluminum finishing chemicals are manufactured according to strict Swiss safety

and environmental requirements and are suitable for outdoor and indoor architectural applications.

The Sanodal® range of dyes, used in this partnership, offers exceptional light and weather

fastness properties, in a broad range of shades.

In addition, based on clients’ complex individual requirements, with Omya, Clariant can offer

technical customer services for all the steps in a production process, operation support, and

workflow optimization, provided locally by Clariant technical centers and regional exclusive

partners wherever possible. This support ensures that dyeing processes are optimized, aiding the

development of special products and solutions to enhance end-products such as car parts,

electrical devices and appliances.

This three-way KTM-2000-Omya-Clariant partnership shows the advantage and possibilities of

working with color and anodized aluminum, and it looks set to continue, “Thanks to the partnership

with Clariant and Omya, KTM-2000 has achieved success and completed some significant

projects, but we believe that the most interesting projects are still ahead!” concludes Gvozdkov.

For more information on Clariant’s aluminum finishing solutions, please visit

www.clariant.com/Aluminum-Finishing.

GLOBAL TRADE MEDIA RELATIONS

Stefanie Nehlsen

Phone +41 61 469 63 63

[email protected]

Follow us on Twitter, Facebook, LinkedIn, Instagram.

Read our latest blog on The Moleculist.

Sanodal® IS A TRADEMARK OF CLARIANT REGISTERED IN MANY COUNTRIES.

Clariant is a focused, sustainable and innovative specialty chemical company based in Muttenz, near Basel/Switzerland. On 31 December

2020, the company employed a total workforce of 13 235. In the financial year 2020, Clariant recorded sales of CHF 3.860 billion for its continuing

businesses. The company reports in three business areas: Care Chemicals, Catalysis and Natural Resources. Clariant’s corporate strategy is

led by the overarching purpose of ‘Greater chemistry – between people and planet’ and reflects the importance of connecting customer focus,

innovation, sustainability, and people.

Clariant’s Business Unit Pigments is a leading global provider of organic pigments, pigment preparations and dyes. The vastly diverse portfolio

corresponds to the high standards for colors and coatings in industrial, automotive and architectural applications. The business unit also provides

solutions for the plastics industry, for special applications in the aluminum, agricultural and consumer goods sector, as well as for traditional

printing processes, inkjet printing and toner applications. The Pigments business unit continues to bring new and innovative materials to the

market, with a strong emphasis on environmental aspects and sustainability.

Blog article and photography can be downloaded from www.clariant.com or www.PressReleaseFinder.com