When you think of respiratory and surgical masks, which are currently

produced predominantly in Asia, ultrasonics is probably not the first thing

that springs to mind. Yet ultrasonic welding plays an important roll in

making these products. As an experienced technology provider for mask

production equipment, Weber Ultrasonics AG now manufactures respiratory and

surgical masks in Germany. This is made possible by the fast and active

support of other companies as well as the huge dedication of its own

employees.

Efforts to stem the spread of Covid-19 make one problem of globalisation

clear: the dependency on low-cost manufacturing countries for personal

protective equipment (PPE). That is why, in addition to protective clothing

and gloves, breathing protection and surgical masks have been in short

supply in Germany and other European countries since the global spread of

the corona virus Sars CoV-2. ‘Since the Sars pandemic in 2002/2003, we have

been producing equipment for the manufacture of different protective masks

made of nonwovens based on thermoplastic synthetics. The equipment is

primarily supplied to customers in Asia,’ reports Christian Unser, Chief

Sales Officer at Weber Ultrasonics AG. It includes components such as

generators, boosters, converters and sonotrodes as well as complete systems

for welding, laminating, cutting and embossing with ultrasound. Producing

masks itself was never an issue for the component and plant manufacturer

based in Karlsbad (Germany) – until the start of March 2020.

Entering into production of FFP respiratory masks

What triggered it was an enquiry from a mechanical engineering customer who

was unable to get filter domes for its special ventilated respiratory masks

in FFP2 protection class as a result of the export restrictions in place

for these products in virtually all countries. ‘Together with the customer,

we developed a plant design for producing the three-dimensional filter

elements in a very short time. The customer immediately placed an order for

three machines,’ explains Christian Unser. In parallel with this

development, Weber Ultrasonics converted the design into a standard machine

for the production of complete breathing protection masks. The first

process step of deep-drawing the masks represented a challenge. This takes

place through hot-forming, which requires a suitable tool as well as

special heating elements and corresponding control units. In order to be

able to produce corresponding prototypes quickly, Christian Unser turned to

a market player that also works in this segment and spontaneously provided a

heating element and control unit. The Head of Design at Weber Ultrasonics

obtained a second one from his former employer. The necessary tool was made

by a neighbouring model maker and long-standing partner of the company

practically overnight. ‘It really is great how different companies have

offered spontaneous support and cooperation,’ comments the Chief Sales

Officer.

60 respiratory masks per hour with one machine

The production of the breathing protection masks takes place with this

standard machine in a multi-stage process. In the first step, an open-pored

fibrebond as stabiliser, a layer of meltblown nonwoven as particle filter

and a layer of spun-bond are shaped through hot-forming. The edges of the

masks are then joined in an ultrasonic welding process. To do this, an

ultrasonic converter converts the electrical signal produced by the

generator into mechanical oscillation. This is transferred via a booster

and a customised welding tool, the sonotrode, onto the surface to be joined.

The frictional heat this generates causes the nonwoven materials to melt

specifically at the edges, where they form a permanent bond without

distorting. At the same time, the reliable, energy-efficient and productive

joining technology ensures a soft and skin-friendly surface. After the

masks are then punched out mechanically, tapes are attached for fastening

them.

The production capacity of the compact standard plant with a single tool is

around 60 breathing protection masks per hour. The aim is to achieve

protection class FFP3 for the masks produced according to the current

standards and to perform an accelerated inspection of corona virus pandemic

breathing protection masks for Germany.

Virtual start-up with real twin for surgical masks

Weber Ultrasonics has also experienced increased demand for production

equipment for surgical masks. The company’s solutions in this segment so

far enable the production of 200 masks per minute. ‘For this application we

are currently working all-out to set up a testing plant at our premises

that will use a newly developed procedure for continuous ultrasonic welding.

This will enable us to increase production capacity to 400, maybe even 600

masks per minute,’ explains Christian Unser. This machine combines the

steps of folding the fabric, integrating the nose wire, vertical and

horizontal welding, welding on an elastic band and separating.

One reason for the fast implementation of this system in the factory in

Karlsbad is the current travel restrictions. ‘We now need to put the plants

into operation virtually at our customers’ premises and to do this it is

important that we have the same performance here,’ says Christian Unser.

‘This also has the positive effect that we can push forward developments

directly on the plant, perform tests for customers and above all produce

surgical masks in large quantities ourselves.’

The respiratory mask after deep-drawing and welding of the edges with

ultrasound.

Photo: Weber_mask production_Final Mask

For the respiratory masks produced according to the standards for

protection class FFP3, an accelerated inspection of corona virus pandemic

breathing protection masks for Germany will be carried out.

Photo:

Weber_Maskenproduktion_Welding2

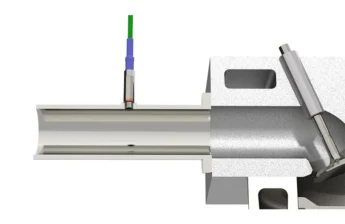

In order to be able to start the production of the respirator masks

quickly, different other companies supplied equipment for the deep-drawing

process of the nonwovens.

Image source: Weber Ultrasonics AG