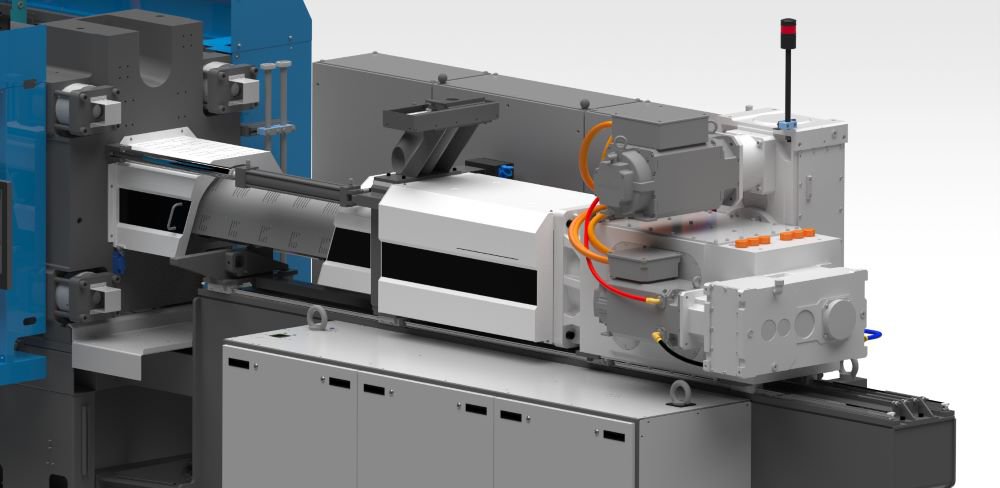

Stork IMM (Stork Plastic Machinery B.V.) has unveiled its new all-electric injection moulding machines. The new range is expected to provide greater sustainability while maintaining the high-performance capabilities seen in the standard Stork IMM machines. Attendees of the K show in Dusseldorf, Germany, this October will be able to see the new machines in the flesh.

Along with the sustainability benefits, the all-electric range offers lower energy consumption, an improved rack-and-pinion drive system, and customisable process tailoring that works with a range of applications in thin-wall food packaging and industrial paints/buckets.

The injection moulding machines specialist has already delivered its all-electric solutions to a series of leading packaging manufacturers across Europe. Stork has gone on to reveal that there is “significant global interest” in its all-electric line, with a “healthy pipeline of orders” to look forward to.

Stork’s injection moulding machinery is ideal for use in the production of food-grade, thin-wall packaging made of polyolefins (PE and PP). Additional proposed key applications include closures, tubs, containers, cups, flowerpots, paint pails, and buckets.

Key features of the new all-electric injection moulding machines:

- Highly flexible and customisable solutions.

- Users can pair the solution with clamping units from 250 to 700 tons with a range of injection units with screw sizes from 45 to 84 mm.

- Achieves 15% more in energy savings compared to similar hybrid machines.

- Operates at injection speeds suitable for thin-wall packaging applications.

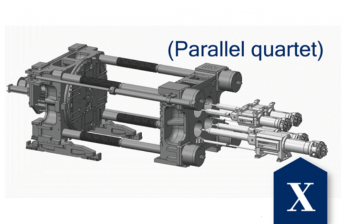

- Features a heavy-duty rack-and-pinion drive with enhanced rigidness and energy efficiency while minimising wear and extending its lifespan.

- Provides greater speed forces for the clamp and injection units compared to ball bearing and spindle drives.

- Includes a breaking energy feedback system where recovered energy is fed back into the customer energy grid.

“This machine extension satisfies growing customer demands for high-performance injection moulding machines that meet sustainability goals for the packaging market,” said Gert Boers, CEO of Stork IMM. “This development reaffirms our commitment to delivering the latest technology that will support a circular economy.”

Source: interplasinsights.com