ALPHARETTA, Ga., April 26, 2013 – Solvay Specialty Polymers, a leading global supplier of high-performance thermoplastics for the automotive industry, will deliver two technical presentations on the use of its high-performance polyamides for engine cooling components at the 8th annual SPE Automotive Engineering Plastics Conference (AutoEPCON) April 30 at Michigan State University’s Management Education Center in Troy, Mich.

First held in 2006, the AutoEPCON features technical presentations on the newest advances in materials technology, predictive engineering, process enhancements, and application developments for thermoplastic and thermoset engineering plastics for the automotive industry. Kirit Desai, technical marketing manager for Solvay Specialty Polymers, and Brad Hakes, engineering supervisor for injection molder MPC Inc., will jointly discuss “Integrating Cooling Components by Using Scientific Molding and the Unique Properties of Amodel® PPA.” The presentation will discuss how OEMs are identifying new ways to reduce the cost and weight of engine cooling components in response to tougher CAFE regulations and stricter emissions standards.

Over the years, thermoplastics have replaced metal for thermostat housings and water inlets/outlets and more recently they are becoming the preferred material for water cooled charged air coolers (WCCAC), exhaust gas recirculation (EGR) cooling, dual-clutch transmission (DCT), and battery-packed cooling, according to Desai.

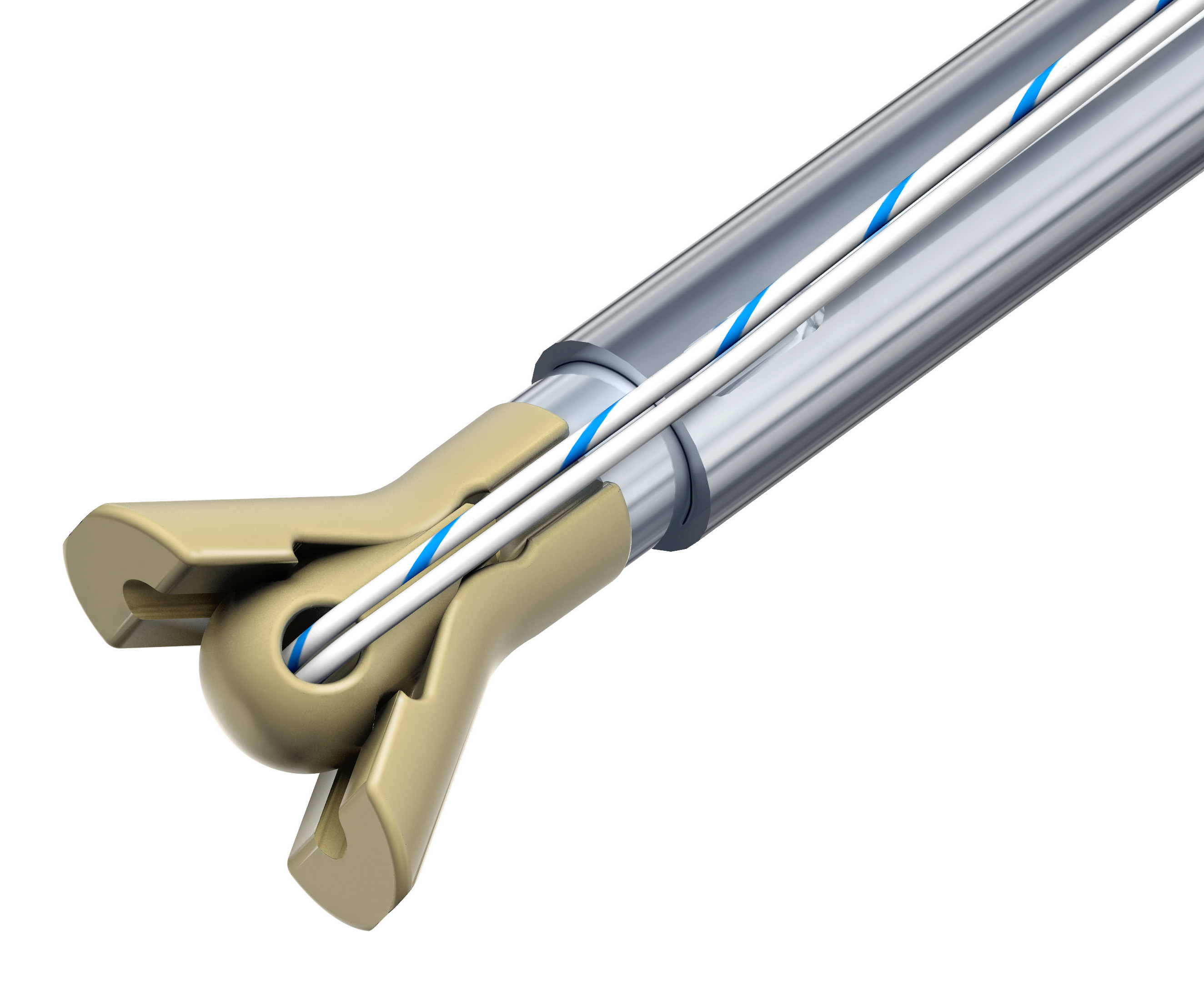

One of the key differentiating factors for Solvay’s Amodel® polyphthalamide (PPA) in engine cooling components is its ability to be injection molded without producing a parting line on the barb of the outlet or inlet tubes. In a typical plastic part, the parting line can be very sharp and cut the tubing during installation, resulting in a coolant leak path. To avoid such a quality issue, OEMs specify no parting line in the barbed area. Solvay’s unique PPA compounds, Amodel® AS-1933 HS and AS-1945 HS, have superior elongation at the recommended mold temperature of 135°C (275°F) compared to other PPAs and polyphenylene sulfide (PPS).

The material’s higher elongation allows injection molders to eject the parts from the mold without producing a parting line in the barbed area. Both Amodel® PPA AS grades reduce cost, use simple tooling, and decrease cycle times. They have been used successfully by many auto OEMs in numerous heating and cooling components. Among the key design guidelines and recommendations: the maximum undercut ratio should be around 8-9% and the ejection angle should be greater than 150 degrees. In case of outlets with a small diameter, it is possible to mold the undercut in the range of 12-13% with a special provision.

Desai and Hakes will also discuss Nissan Motor Co.’s unique 10-port water outlets for 1.6-L to 2.5-L engines, which MPC injection molded using Solvay’s Amodel® PPA. The material’s high elongation permits the elimination of the parting line commonly required for injection molding and part extraction to produce this complex part at a cost savings and 450-gram (1-pound) weight reduction versus metal.Meanwhile, Andre Carvalho, global automotive market manager for Solvay Specialty Polymers, will discuss “Engine Thermal Management Technologies Benefit from High-Performance Polymers.” The presentation will outline Amodel® PPA’s wide-ranging performance capabilities as a replacement for competing nylons, PPS, and metal.

Amodel® PPA has been the preferred material in engine cooling components because it retains its mechanical properties over 5000 hours in ethylene glycol (engine coolant). Other competing materials such as conventional nylons have failed to withstand the requirements of these systems due to significant loss of mechanical properties when exposed to ethylene glycol.

Compared to typical nylons, Amodel® PPA has higher thermal capabilities and is stronger, stiffer, and less sensitive to moisture. It retains its excellent mechanical properties – including fatigue and creep resistance – over a broad temperature range in humid and chemically aggressive environments.Two case studies will offer insights on the selection of Amodel® PPA over other nylons and PPS in thermostat housings, electric valves, electric water pumps, and other components of coolant circuitry for automotive fluid thermal managemen.