ALPHARETTA, Ga., November 27, 2012 – Solvay Specialty Polymers, a leading global supplier of high-performance thermoplastics for the automotive industry, will deliver a technical paper on the use of its high-performance polyamides for automotive fuel systems at the upcoming SPE ANTEC 2012 conference Dec. 6-7 at the Renaissance Mumbai Convention Centre Hotel in Mumbai, India. The new technical conference, sponsored by the Society of Plastics Engineers (SPE), is the first ANTEC to be held outside of North America. The program will span two full days, consisting of six sessions per day in six major topic areas.

More than 100 technical and technical/commercial papers will be presented. The format will replicate SPE’s very successful annual ANTEC conferences held in the U.S. Ahir Mathkar, Technical Marketing Engineer, and Georgie Mathew, Sales Development Manager, both with Solvay Specialty Polymers India, will discuss “Polyphthalamide (PPA) to Meet India’s Emission Control Requirements for Auto Fuel Systems.” The presentation will discuss the automotive market in India which is moving toward stricter vehicle emissions requirements.

This is a trend that affects the fuel system and consequently its material specifications and construction, according to Solvay. The new materials that are required to meet the performance challenge for fuel emissions must provide higher temperature during usage along with chemical resistance to different types of fuels encountered in the Indian market, ranging from gasoline CE5 (5wt% ethanol content), diesel, and its blends with biodiesel. In India, the Bharat Stage-IV (BS-IV) is predominant, with reasonable similarity to the Euro IV norm.

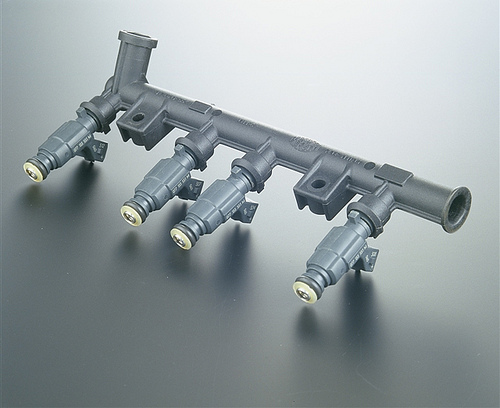

A class of high-performance polyamides called polyphthalamide (PPA) plays an important role in meeting the new demands and optimizing the performance of the fuel system. PPA increases fuel efficiency by lightweighting the components and as a consequence reduces greenhouse gases (GHG). PPA compounds based on glass fiber, mineral, and hybrid fillers are uniquely positioned to offer solutions that allow original equipment manufacturers (OEMs) and fuel systems suppliers to meet cost and performance targets.

Based on the need to find alternatives to conventional polyamides, PPA thermoplastic, a semi-aromatic polyamide (AmodelÒ PPA from Solvay), was characterized for use in contact with biodiesel B30 and ethanol 100%, providing extrapolation over biodiesel content in diesel and ethanol content in gasoline fuel currently used in the Indian marketplace. These bio-based fuels can have an adverse effect on the long-term performance of aliphatic polyamides such as PA6, PA6.6, and PA 12.

However, semi-aromatic polyamides such as PPA have demonstrated superior performance in these bio-fuel applications, retaining their properties over the long term, according to Solvay.The paper will present property comparisons and design recommendations. It will also include detailed analysis showing why PPA is an ideal material choice for fuels currently used in the Indian market.