At the current Intersolar Europe trade fair in Munich, Schott Solar and BASF jointly present

a new roof-integrated photovoltaic technology based on Schott’s Advance series of solar modules. The concept comprises two parts: a specially developed, multi-functional pan made from the BASF resin Ultramid B High Speed and a frameless double glazed PV module from Schott.

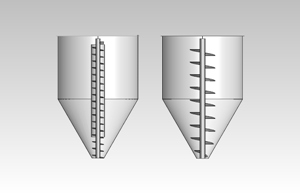

The new product is designed for large roof areas on industrial or agricultural buildings and is very light and easy to install. The one-piece plastic pan, which can be installed directly on the roof substructure of a building in place of conventional roofing, combines several functions and employs a new fastening method.

The new product is designed for large roof areas on industrial or agricultural buildings and is very light and easy to install. The one-piece plastic pan, which can be installed directly on the roof substructure of a building in place of conventional roofing, combines several functions and employs a new fastening method.

After the plastic pan has been fastened to the roof sub structure at four points, the only remaining step is to insert the rugged double-glazed module into the pan’s precision mounting system and secure it in position by means of an integrated latch.

The PV module from the Schott Protect series employs double-glazing technology for protection against rain, hail and other adverse weather conditions. To ensure safe handling of the double-glazed module, handles that are also made from Ultramid are provided on the back.

According to the two companies’ joint press release, such design makes it easy to carry the PV module, place it on the integrated support edges of the plastic pan and simultaneously secure it at all four attachment points quickly and without the need for tools by sliding the module into the latching mechanism on the pan (Click & Go). The easy handling provided by the built-in handles permits use of frameless double-glazed modules, thereby preventing the accumulation of dirt on the surface.

Moreover, the new bayonet connection and screw free attachment to the pan provide automatic tolerance compensation. The pan itself is stackable, thus reducing shipping volume.

Channels are integrated into the pan to ensure that rainwater drains away. Additional channels in the pan’s structure facilitate the installation of electrical cables. Because of the large opening in the center of the pan, the plastic part of the 1.7sq m photovoltaic module weighs only 8kg and has adequate back ventilation. As with a classical roof tile, specially designed edges permit overlapping with adjacent modules, providing further protection against rain.

The companies says that the approximately 1.2×2.0m plastic pan requires an easy-flowing resin in order to produce the part by means of conventional injection molding. For this reason, BASF’s Ultramid B High Speed, one of the new especially easy-flowing grades in the polyamide 6 range, was chosen. The good flow characteristics of the resin, in conjunction with the opening in the pan, also help to reduce manufacturing costs as it can be processed on injection molding machines with a lower clamping force.

The toughness of this special Ultamid grade also makes it suitable for photovoltaic applications according to the release. It shows high strength even at elevated temperatures, as well as resistance to UV and weathering. In terms of fire behavior, Ultramid B High Speed satisfies the criteria required for such construction applications (material class B2).

Source : www.adsalecprj.com