SABIC, a global leader in the chemical industry, today has announced the development of a new technology and range of dedicated polyethylene (PE) and polypropylene (PP) resins that mark a significant leap forward in the performance profile of polyolefin pressure pipes. Together with Tecnomatic and aquatherm, two major specialists in pipe manufacturing, the technology is being advanced from concept to reality. As ‘Golden Sponsor’ of the International Plastic Pipes XX (PPXX) Conference and Exhibition (6-8 September 2021) in Amsterdam, SABIC introduced the new concept during the conference and presented the technology in the PPXX Technical Sessions.

There is an urgent need for more durable and reliable as well as cost-efficient and sustainable pipe systems to meet the potable water and sanitation needs of an ever-growing global population. Since the introduction of polyolefins for pressure pipes, continuous efforts have been made to improve the performance levels and expand the application scope of polyolefin pipes. SABIC has now succeeded in optimizing the formulation of dedicated PE and PP resins for biaxial stretching that will allow manufacturers to boost the key properties of pressure pipes to unprecedented levels. The new resins in combination with the BiAx stretching technology will enable a new generation of lighter and stronger as well as energy- and cost-efficient pipe systems.

Benefits in performance and sustainability

SABIC’s new BiAx Pipe technology offers substantial improvements over incumbent polyolefin pipes across the entire range of performance criteria. Higher resistance against internal pressure enables wall-thickness reduction and thus can reduce material use by at least 30 percent. Superior resistance to slow-crack growth (RC) facilitates trenchless pipe installation. In addition, the very smooth inner wall surface reduces the energy required for pumping. The technology renders the pipes more abrasion resistant and prolongs their lifetime. Combined, these characteristics provide a major leap forward.

In addition, the new PE and PP pipes promise better resistance to disinfectants, a lower coefficient of linear thermal expansion (CLTE) and improved low-temperature impact strength.

Connecting across the value chain

SABIC is partnering with leading players in the pipe industry to validate and accelerate the time to market of its new BiAx Polyolefin Pipe technology

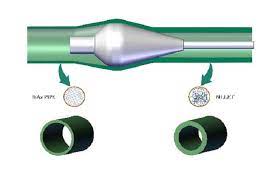

As part of these joint efforts, Tecnomatic, an Italian pipe manufacturing equipment specialist, has installed a fully integrated continuous BiAx pipe extrusion line for evaluation, trials and optimization of the process with dedicated SABIC resins. On this line, pipes are first conventionally extruded with thick walls and small diameters, then drawn over a heated mandrel and stretched in two directions to obtain larger diameters and thinner walls. This gives them their characteristic BiAx properties.

Another partner in this project is aquatherm, a world leader in PPR pipe systems with extensive product, application and market knowledge. The company targets to introduce SABIC’s advanced biaxially oriented pressure pipe technology in a wide range of diversified application areas.

For a closer look at the new technology, view SABIC’s BiAx Pipe video here.

For more information about the new BiAx Polyolefin Pipe technology, please contact us via www.sabic.com/en/contact

ABOUT SABIC

SABIC is a global diversified chemicals company, headquartered in Riyadh, Saudi Arabia. It manufactures on a global scale in the Americas, Europe, Middle East and Asia Pacific, making distinctly different kinds of products: chemicals, commodity and high performance plastics, agri-nutrients and metals.

SABIC supports its customers by identifying and developing opportunities in key end-use applications such as construction, medical devices, packaging, agri-nutrients, electrical and electronics, transportation and clean energy. Production in 2020 was 60.8 million metric tons.

The company has more than 32,000 employees worldwide and operates in around 50 countries. Fostering innovation and a spirit of ingenuity, SABIC has 9,946 global patent filings, and has significant research resources with innovation hubs in five key geographies – USA, Europe, Middle East, South Asia and North Asia.

ABOUT AQUATHERM

aquatherm GmbH, based in Attendorn, Germany, is the world’s leading manufacturer of plastic piping systems made of polypropylene for plant engineering and building services. The areas of application include drinking water applications, heating system construction, fire protection sprinkler systems, air conditioning and refrigeration technology as well as surface heating and cooling systems. The range includes more than 17,000 items in six product lines.

In order to guarantee the worldwide availability of the products and to offer local service, aquatherm works closely with longstanding partners around the world in more than 70 countries. The company employs approximately 600 people in Germany, Italy, England, the United States and Canada. Production takes place exclusively at three German locations, so customers all over the world can rely on innovative and safe PP-R piping systems of the highest quality ‘100 percent made in Germany’. Visit www.aquatherm.de for further information.

ABOUT TECNOMATIC SRL

Located in Bergamo, in the heartland of the Lombardy region (Italy), Tecnomatic SRL offers machines and turnkey projects for the plastic pipe industry. Since 1977, a continuously evolving company able to grow in line with the market changes and to consolidate its name on the main worldwide market for manufacturing of technology. Identifying the customer needs, analysing the feasibility of the project, defining the sale offer and verifying the production costs are the starting point. Passion, technology and employees’ qualities the means to conceive the ideal solutions with an appropriate balance between design, innovation and production needs. Further information can be obtained at tecnomaticsrl.net.

SABIC has developed a new range of PE and PP resins that offer significant improvements in key performance properties for biaxially stretched pressure water pipes.

SABIC Media Contacts

Mohammed I Al-Hassan

E: [email protected]

T: +966 11 225 9267

Marketing Solutions

Kevin Noels

E: [email protected]

T: +32 3 31 30 311

This press release and relevant photography can be downloaded from www.PressReleaseFinder.com.

Alternatively for very high resolution pictures please contact:

Kevin Noels ([email protected], +32 3 31 30 311).