NEW DELHI, India, October 5, 2012 – To meet the demands of India’s fast-growing light emitting diode (LED) lighting market – estimated to top $470 million by 20151 – SABIC’s Innovative Plastics business is spotlighting its industry-leading portfolio of LED material solutions here at the first Light India 2012 expo, from Oct. 5-8. The company is exhibiting, in hall 12A, booth #L16, such signature LED product technologies as its LEXAN™ LUX family of polycarbonate (PC) resins, LEXAN SLX and EXL copolymers and LNP KONDUIT™ specialty compounds.

These high-performance thermoplastic technologies demonstrate SABIC’s deep understanding of its customers’ requirements for maximizing LED light output, heat management, safety and sustainability. “The LED market in India is dynamic and growing by double digits,” said Koka Venugopal, business leader, India, Innovative Plastics. “In this environment of rapid change, SABIC’s high-tech materials, technical expertise and services are helping lighting customers streamline the creation of new LED products so they can quickly capitalize on new opportunities.

A key benefit of engaging with SABIC is the proactive work we have done to create materials that are the highest quality, deliver top-level performance and comply with global environmental standards. We are strongly focused on India’s lighting market and are excited to be participating in Light India 2012 to showcase our LED materials portfolio and demonstrate how it can help our customers succeed.”

High-performance Materials for Diverse LED Applications

LEXAN LUX resin series is a specially formulated range of optically clear/diffused grades designed to cater to the increasingly diverse and growing LED lighting segment. LEXAN LUX resins meet the challenges of LED applications for initial transmission heat, impact and ultraviolet (UV)/weatherability resistance, delivering sustainable performance for a longer life-span. LEXAN LUX grades additionally offer a wide window of flow properties, ranging from extrudable to high flow, as well as flame resistant (FR) capabilities. One of the most important characteristics is its wide variety of optical effects, each striking the optimum balance of maximum light transmission for a given diffusion.

With this package, customers can find customized grades for LED applications of varied power ratings and product designs. The versatility of this material’s usage for diffuser applications can be seen at the booth in our samples of ceiling downlights, table lamps, and retrofit bulb domes. UV-stable LEXAN SLX copolymers deliver enhanced weatherability for outdoor lighting applications such as streetlights. These materials also provide excellent heat and impact resistance in addition to color retention. Another choice for exterior lighting is the LEXAN EXL copolymers series, which offers improved weatherability, high ductility at low temperatures and good chemical resistance.

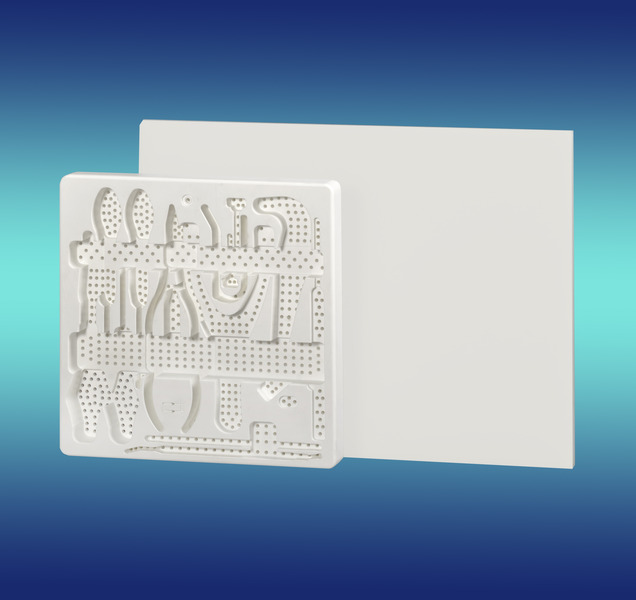

Specialized LEXAN resins with high reflectivity for non-automotive lighting reflectors are also on display. These high-reflectivity materials are available with non-brominated, non-chlorinated FR performance meeting the UL 94-V0 standard.

In addition, the company is exhibiting heat sinks molded from LNP KONDUIT compounds, which are thermally conductive, electrically isolative materials and which offer greater design freedom than traditional approaches to thermal management. Because this material can be injection molded, it enables new designs for maximizing heat dissipation. Using KONDUIT compounds, heat sinks capable of being used in LED retrofit bulbs up to 12W can be designed.