Grafenberg, May 26th, 2015. RAMPF Polymer Solutions now has a comprehensive range of high-performance assembly adhesives on the market. Its polyurethane, epoxy, hybrid, silicone, and hot-melt systems ensure reliable bonding in a wide range of applications – including in the au-tomotive/transportation, filter, electrical/electronics, wood processing, lightweight construction, and white goods sectors.

RAMPF Polymer Solutions, a leading developer and manufacturer of reactive plastic systems based on polyurethane, epoxy, and silicone, has broadened its portfolio by adding high-performance assembly adhesives to its customized casting resin systems for sealing, casting, and coating.

“Our aim was to develop superior adhesive solutions for the widest possible range of assembly applica-tions,” explains Dr. Klaus Schamel, Managing Director of RAMPF Polymer Solutions. “And we have suc-ceeded in developing a very broad spectrum of properties that enable us to offer our customers tailor-made, high-quality polyurethane, epoxy, hybrid, silicone, and hot-melt systems.”

Dr. Klaus Schamel, Managing Director of RAMPF Polymer Solutions (left), and Dr. Wolfgang Hodek, Senior Key Technology Manager Adhesives, are driving the development of high-performance adhesive systems full speed ahead. “The launch of our assembly adhesives portfolio will soon be followed by the introduction further high-quality adhesives,” says Dr. Schamel.

RAKU-PUR: 1- and 2-component polyurethane-based adhesive systems

> Low to high viscosity, stable

> Good adhesion to plastics, metals, wood and engineered-wood materials

> Universal use – from small- to large-scale applications

> Exposure times from a few minutes to more than 3 hours

> Good temperature resistance from -40 to +100°C

> Good media resistance

RAKU-POX: Epoxy-based adhesive systems

> Pot life and exposure times from a few minutes to 3 hours

> Good adhesion to metal (including aluminum)

> High temperature resistance from -55 to +180°C

> High chemical resistance

> Cures at room temperature

RAKU-SIL: 1- and 2-component silicone-based adhesive systems

> Broad range of open times

> High-strength elastic adhesion and sealing

> Extremely water repellent

> Universal adhesion, even on metals

> High chemical resistance

> High temperature resistance from -60 to over +200°C

> High physical resistance across the entire applications temperature range

> High UV stability

RAKU-MELT: Hot-melt adhesive systems

> Thermoplastic or reactive

> Exposure times from a few seconds to more than 20 minutes

> Quick initial bonding strength

> Applied using a roller, spray or slot nozzle, or dot or bead application

> Suitable for bonding various plastics, metals, wood, and paper

> Versatile use across a wide range of temperatures

Customized solutions

Dr. Wolfgang Hodek, Senior Key Technology Manager Adhesives at RAMPF Polymer Solutions, is con-fident that “our products will succeed on the market thanks to their high quality and customer-specific design. By heavily prioritizing R&D and utilizing our highly effective production processes, we are able to rapidly translate the needs of our customers into high-performance products.”

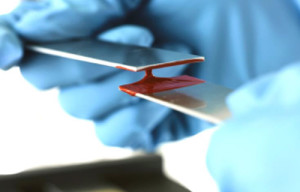

The focus of further developments now lies in optimizing the mechanical properties of tough-elastic reac-tion adhesives, particularly for fiber-reinforced composite materials, “which includes using the latest raw materials in hybrid (silane-functionalized) prepolymer technology,” says Hodek.

In the laboratories of the RAMPF Innovation Centre in Grafenberg, adhesives’ properties such as wetting, open time, and initial strength are tested according to international standards.

Besides these basic products, RAMPF Polymer Solutions is also able to provide precise solutions to meet very specific industrial requirements. “As a strong development partner with a large laboratory and comprehensive applications technology, our clearly defined aim is to lead the market in individual seg-ments,” Dr. Schamel points out.

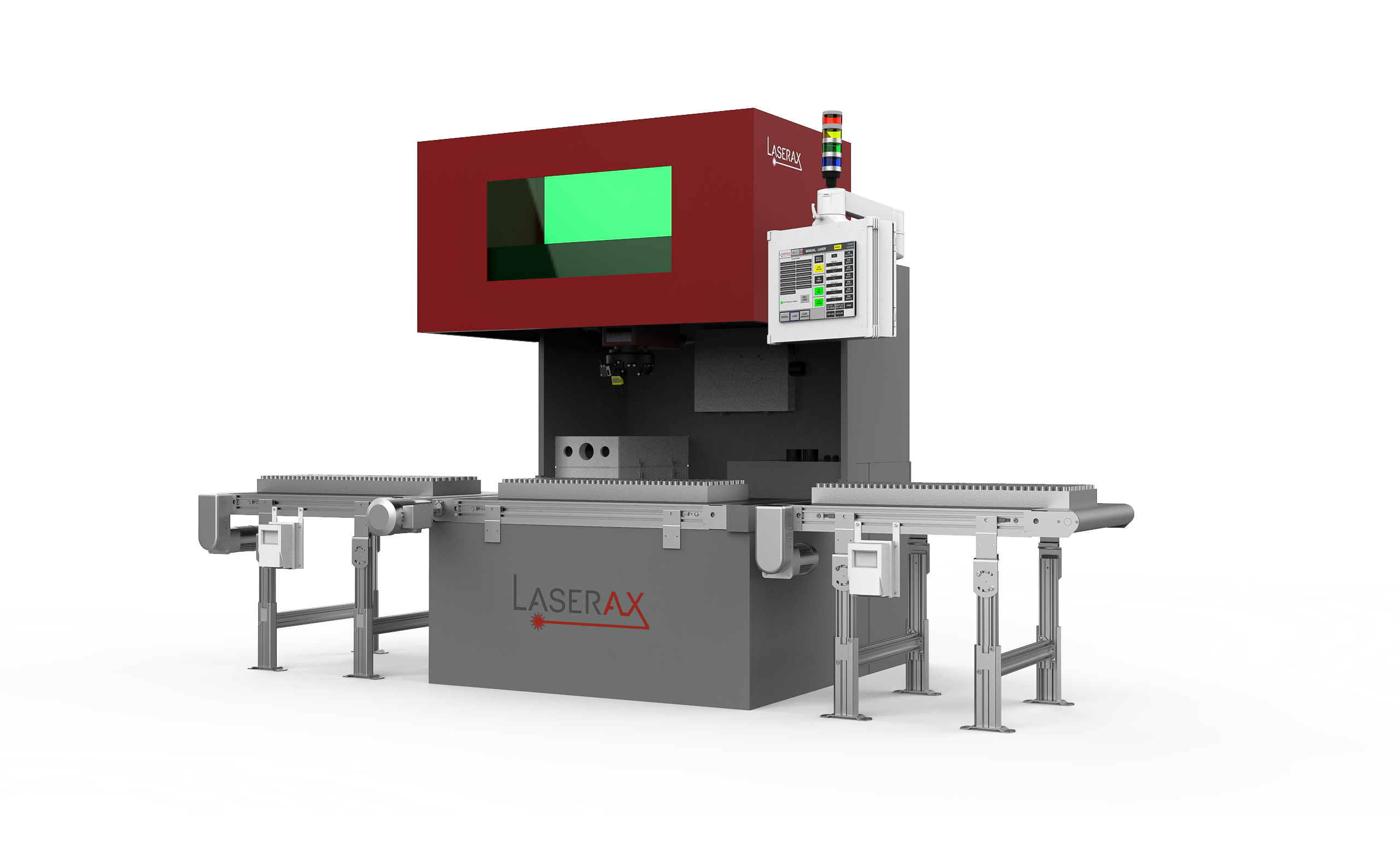

Material and machine from a single source

The synergies utilized with RAMPF Production Systems, one of the world’s leading manufacturers of low-pressure mixing and dispensing systems and renowned automation specialist, also help optimize the development, testing, and applications of adhesives. “The increasing requirements being made on bonded systems – for instance in terms of environmental influences, required strength, and curing times – call for sustained efforts to keep on optimizing adhesives. These factors can influence the processing properties, which means the mixing and dispensing systems then also need adapting accordingly,” ex-plains Bernd Faller, Managing Director of RAMPF Production Systems. “A very close collaboration is essential between the adhesive manufacturers and plant manufacturers in order to develop the best so-lutions. This high degree of collaboration occurs on a daily basis between RAMPF Polymer Solutions and RAMPF Production Systems.”

Website: www.rampf-gruppe.de