PTi (Processing Technologies, LLC), a manufacturer of single screw extrusion systems, will be showing the TITAN Plus controller at NPE 2009, a triennial plastics trade fair held from June 22 to 26 in Chicago. Both TITAN and TITAN Plus are based on the rugged and dependable Allen-Bradley ControlLogix software platform and the PanelView operator interface.

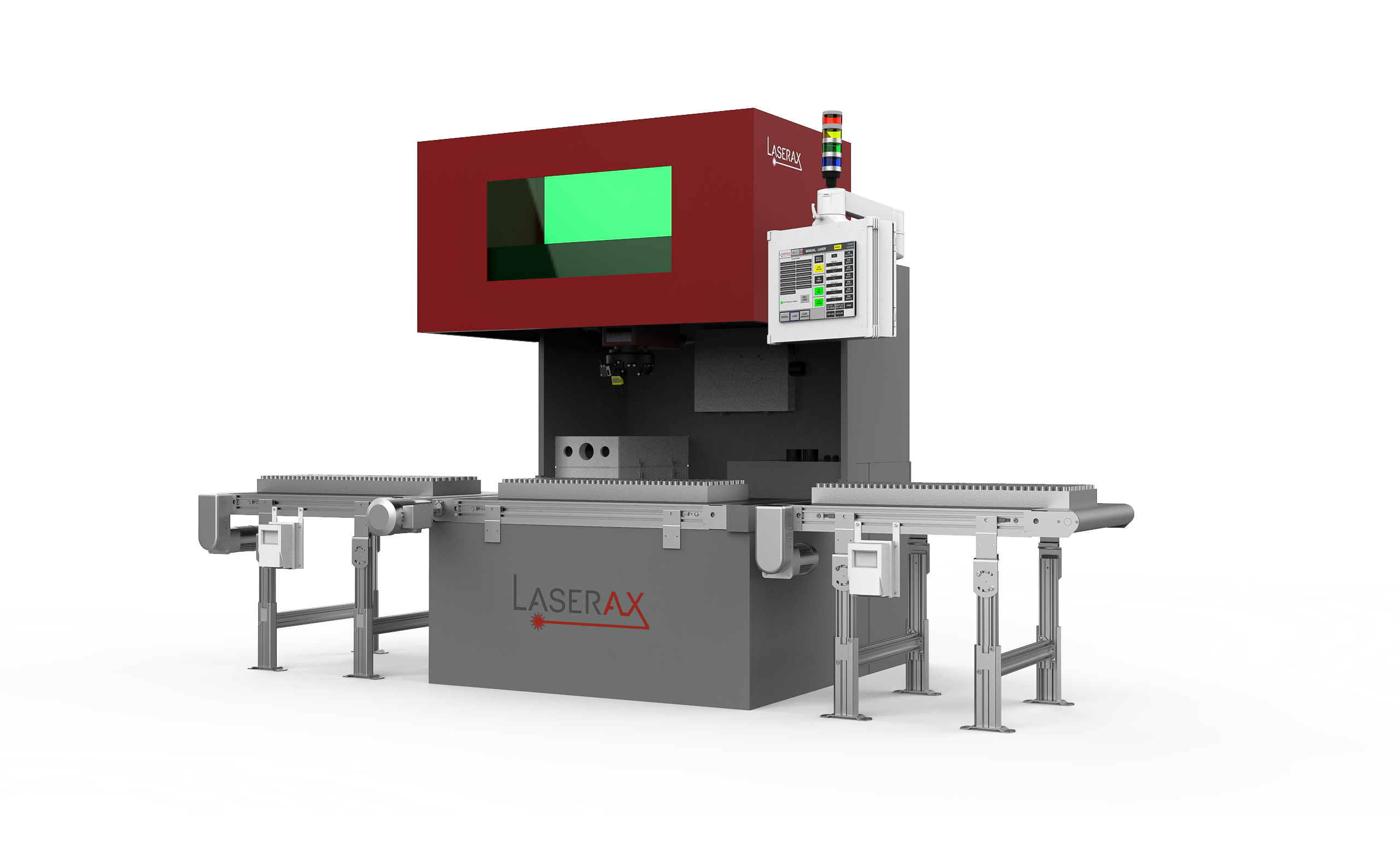

The TITAN system enables operators to consistently run complex sheet extrusion systems across a wide range of operator skill sets that are common in today’s production facilities. TITAN control systems include full machine control functions such as start/stop functions, drives, temperature loops, machine status display, alarm/faults status, recipe creation, data logging, trending and print screen functions. The system is housed in a newly designed ergonomic console with unique features such as a triple touch-screen capable panel that swivels 180 degrees; printer access and storage cubbies; durable work surface; USB and AC ports/plugs; alarm light bar; and optional integral seat.

TITAN Plus comes with three control screens at the operator station. Beefed-up computing power gives the TITAN Plus expanded data logging with additional capacity for storing and displaying historical and real time production information. The operator also can view operations manuals and machine drawings on the screen. A color printer is included with the unit.

Using a two or three screen console that swivels 180 degrees, the operator can more easily make changes on the machine, according to David Dorosa, Electrical Engineering Manager. One example is adjusting the gap on the chill rolls. Utilizing VIDEOGAP technology, a live video feed from cameras on the machine can roll on one screen, while the operator can make gauging adjustments and see the results on the other screens.

Source: plastics.2456.com