Nordson XALOY will introduce a new bimetallic barrel alloy which exhibits greater corrosion resistance than comparable general-purpose iron-based inlays currently standard in Europe.The X220 inlay for extrusion and injection molding barrels is an alloy of iron, boron, and chromium, with a chromium content more than double that of the X200 alloy already available from Nordson XALOY and 40% greater than a standard alloy widely used in Europe.

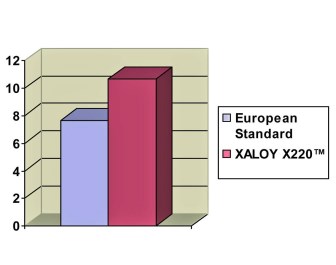

In acid immersion tests by Nordson XALOY, the new X220 alloy exhibited a 46% improvement over the European standard material in terms of sample weight loss in sulfuric acid, and a 31% improvement with hydrochloric acid.In both acid tests, the X220 alloy outperformed X200, an iron-boron-chromium alloy already available from Nordson XALOY, and in all corrosion tests the X220 outperformed the European standard material.

“The superior corrosion resistances of Nordson XALOY’s X220 alloy enhances throughput and reduces downtime for extrusion processors and enables molders to achieve consistent, on-specification production,” said David Hotchkiss, Global Product Manager. “As a new entry in the world’s broadest range of single- and twin-barrel products, it extends our ability to meet the full spectrum of processor needs.”

Source: www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-67008359/Article.aspx