Dynisco, a supplier of measurement and control solutions for extrusion and other plastics processes, has launched a new small granulator fitted for plastic material testing laboratories.

The new granulator is, according to Matthew Caslow, Global Support Manager of Dynisco, suitable for grinding production plastic parts for material testing and analysis. It also allows technicians to granulate lab scrap such as samples from melt-flow tests, rheometer tests, tensile tests and capillary rheometer tests, keeping this material out of the waste stream.

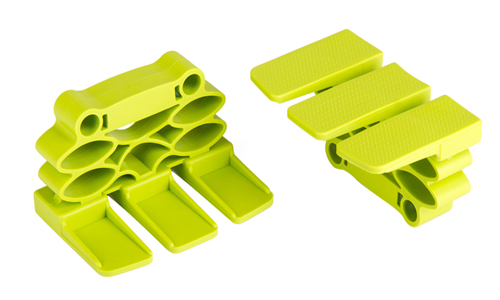

The granulator is powered by a 5-hp electric motor, which drives an oversized flywheel to increase rotational momentum and decrease energy consumption. The slow-speed (200-rpm) rotor has three rotating knives and two stationary bed knives counter-slanted to produce a scissor-like cut. These features help produce a clean consistent regrind with a minimum of dust and fines. Along with rotating sidewalls in the 6.5- by 8-inch cutting chamber, they also minimize heat generation to prevent the polymer from softening and smearing during granulation. Three different screen sizes are available to produce regrind from 3/16 to 5/16 inch. Screens are reversible for service longevity.

The clamshell-design cutting chamber and drop-down screen cradle allow easy access during cleaning and knife changes. All maintenance can be performed from the front of the machine.

Available options include:

# Automatic vacuum or compressed-air unloading of the granulate catch bin

# Bin-level indicator light or signal to unloading system

# Sound enclosure

# Clean-room design with fully baffled in-feed and HEPA filtration.

Source : www.adsalecprj.com