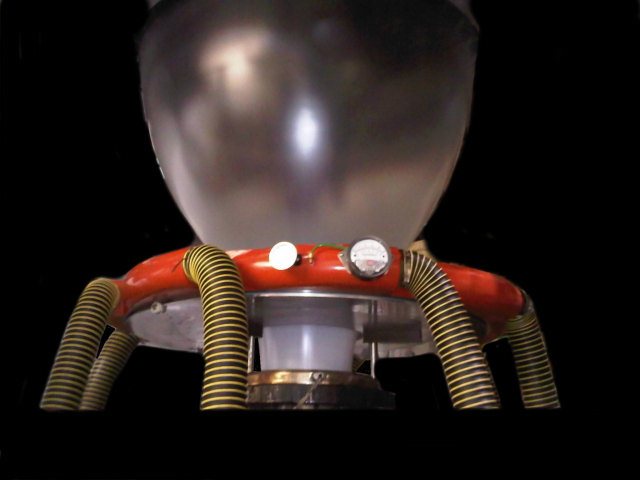

MISSISSAUGA, ONTARIO, CANADA– Plastic blown film processors seeking to improve film quality, reduce scrap and improve yield can now do so with the new Saturn Echo 20.20 bubble width control from Future Design Inc., a Gloucester Engineering Company.

In operation, the new Saturn unit maintains the film (tubing) diameter to ensure the layflat width is as close to the specified parameters as possible. By running tighter layflat tolerances, customers can reduce their trim and scrap. Further, the bubble width control assists in the recovery of bubble breaks.

Offered as a retrofit for nearly any make or model of non-IBC (internal bubble cooled) blown film system, the new Saturn bubble width control will not only reduce costs, but also will pay for itself in many ways including reducing the number of customer returns. Specific benefits include improved quality, extrusion rate, yield, operator reaction time, customer trust and most important to the processor, an improved bottom line.

Future Design Inc., a Gloucester Engineering Company, manufactures a wide range of beneficial products for the flexible packaging industry. The firm is noted for their blown film bubble management expertise and products including their Saturn™ and Perfect Balance ™ air rings, SES evacuation systems, patented Escort collapsing frames and Little Giant narrow web/lab lines. For more information on the patented, Web: www.futuredesigninc.com.