K2 Polymers Ltd in the UK has selected an MRS Extrusion System from Gneuss Kunststofftechnik GmbH from Germany for reprocessing heavily contaminated Nylon 11 regrind.Reground Nylon 11 is available in some quantities when deep sea oil pipes are scrapped after having been recovered from the sea floor from depleted oilfield.

This material is contaminated with oil, as a result of years of use. Some of this oil is on the surface of the material, some oil has diffused into the polymer itself, which poses various problems when processing.Gneuss says with its Multi Rotation System (MRS) extruder, the processing and decontamination of Nylon 11 material can be carried out in one step. No complicated, environmentally problematic and expensive washing of the material prior to extrusion is necessary. The extraction of the oil is done with the patented processing technology of the MRS extruder, with its extremely high devolatilising capacity, which is approximately 25 times greater surface area exchange rate under vacuum than an equivalent twin screw extruder.

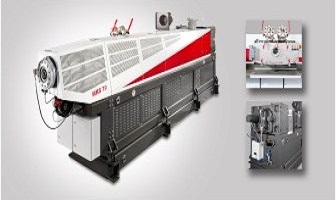

As said, a vacuum of only 25-40mbar is necessary in order to reliably remove the volatiles from the melt, including the necessary quantity of oil. In the case of K2 polymers, an MRS 70 with a throughput rate of up to 150kg/h is selected. The system also includes an RSFgenius Rotary Melt Filtration System for efficient, process and pressure constant of solid and semi-solid contamination.