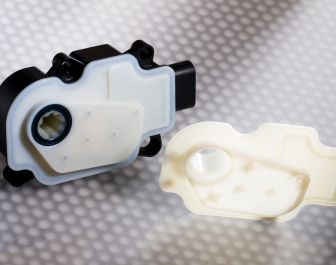

Germany Motor developer Precision Motors Deutsche Minebea (PM DM) is using BASF’s new polybutylene terephthalate (PBT) grade, the laser-transparent Ultradux Lux to produce the housing cover of its novel control module.

The small actuator consisting of gears, an electric motor and an electronic unit serves to control the air flaps in motor vehicles, which said to be improving aerodynamics and lowering CO2 emissions.

The laser-transparent PBT, Ultradur Lux accounts for stiffness and dimensional stability, even in damp environments, which are important properties for electric and electronic products. Its transparency toward near-infrared light is in 800-1100nm wavelength, the crucial range for penetration laser welding, which according to BASF allows the material to be welded faster than other PBT grades available on the market.

Moreover, the processing window is considerably wider and the risk of damage to the material is lower. The grade used here, Ultradur LUX B4300 G4, is reinforced with 20% glass fibers.

In the future, it will be possible to control the air flow that cools modern car engines, achieving greater efficiency: movable air flaps or vanes installed behind the radiator grill can be closed by the actuator in response to cold weather, helping the engine to reach its operating temperature more quickly.

At the same time, the closed vanes reduce air resistance when the vehicle is travelling at high speeds, which also saves fuel. PM DM developed this actuator in a joint effort with Röchling Automotive, a supplier to the car industry. The Germany-based inventor of air flap systems integrates the modules into its components and also takes care of the validation for its customers. The performance parameters of the PM DM actuators as well as their compact design allow suppliers to respond flexibly to the requirements in various types of cars.

SOURCE : http://www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-125496/Article.aspx