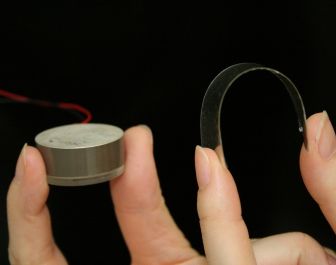

Johnson Controls is applying its expertise in natural fiber processing technology for interior components to vehicle exteriors; the company is using liquid resin press molding to enable series production of carbon fiber body parts. The company says that it is already supplying a well-known automotive manufacturer with its carbon components.

Previously, the production of very light carbon components involved a great deal of effort and a considerable amount of manual labor.

The new process is based on a wet press process used by Johnson Controls since 2003 to produce wood fiber components for vehicle interiors. In the newly adapted process, a carbon fiber mat pre-moistened with resin is placed between the forming tools and then pressed. During the pressing cycle, the excess resin leaks onto the edge of the mold. This provides a very high fiber density in the body parts.

We are one of the pioneers in the automotive industry for large-scale production of carbon parts, thanks to our innovative production process. We are pleased to be able to transfer that technology for use in vehicle exteriors.

Source : greencarcongress.com