The composites market is booming with an average of 6% growth per year since 2010, according to JEC Group, the largest composites industry organization in Europe and organizer of JEC Europe Show.

With a growing demand for better environmental impact reduction and costs savings, composites are used more and more often to lighten structures, aircraft, and vehicles in general, thus improving energy efficiency. JEC Group, the largest composites industry organization worldwide, has identified five developments in the market that could grow even bigger by 2030.

“Indeed, the global composites market represents 81.6 billion euro in value for 2012. This market is growing at an average of 6% per year. The composites industry is growing in volume in correlation with the increase of gross domestic product by country. And penetration continues in some sectors like Aeronautics. For instance, we expect the Composites market for Aerospace to be four times bigger than today by 2030.” Frédérique Mutel, JEC Group President and CEO, said.

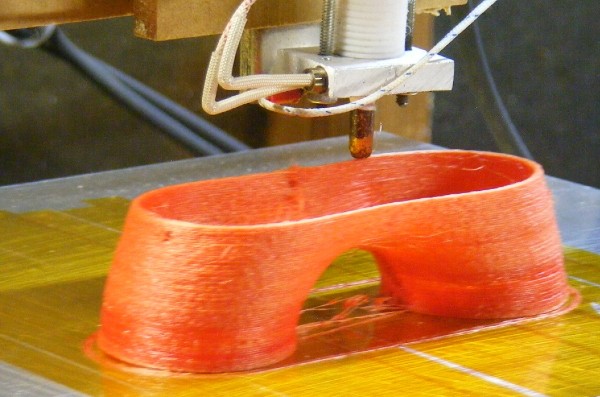

As new applications in high volume markets continue to appear for instance in Electricity, Electronics & Consumer Goods, especially in Asia, Mrs Mutel identifies five trends that will boost the market volume to 12 million metric tons by 2017, as compared to 9.2 million in 2012. Converting processes towards mass production: over the past few years, the composites sector has developed its ability to convert processes, including for large and complex-geometry parts. Large companies have invested heavily in these new technologies, which lower the cost of composite parts. For example, thermal curing technology enables mass production in the aerospace and the automotive sectors.

Developing properties of thermoplastics: new resins, fibers and additive have been developed in order to improve mechanical, thermal or conductivity properties. This will have a huge impact on the automotive sector notably thanks to the revolutionizing thermoplastics resins. Turning materials into smart composites: smart composites with sensors which enable companies to foresee the ageing process of the parts they create. They also enable the structures to repair themselves.

Conquering new application sectors: new sectors have started to turn to composites such as for instance, the energy sector (transmission and distribution), electronics and consumer goods (cell phones, tablets…) etc. Using greener materials: nowadays, finding a way to recycle has become one of the priorities. Recyclates are now used to produce new composites and are at use in other industries such as cement work.

Source: http://www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-67003224/Article.aspx