Ironjaw (Lisbon, Portugal), a new technology that boosts the clamping force on injection molding presses, has been launched by Bruno Machet, owner of Compose, and Alex Guichard, the founder of RocTool and Revology.

Ironjaw (Lisbon, Portugal), a new technology that boosts the clamping force on injection molding presses, has been launched by Bruno Machet, owner of Compose, and Alex Guichard, the founder of RocTool and Revology.

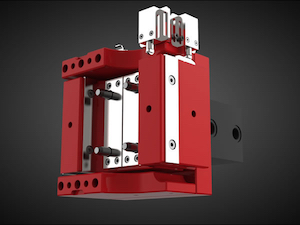

It promises to increase the capacity of injection presses with 30 to 60% more clamp-force. The technology can be adapted to all types of molds, said the developers of Ironjaw.

“Our system has been successfully tested on several million R&D-stage parts, leading us to create a company that is dedicated to the technology in order to provide the world’s plastics processors and molders with a cost-effective solution to boost press capacity,” explained IronJaw founder and CEO Bruno Machet. The system took five years to develop and has a number of international patents.

Ironjaw uses a system of steel jaws to clamp the mold. “The technology produces spectacular gains in molding pressure—up to 60%, depending on the configuration,” claims Machet, “and decreases or even eliminates flash. It works with all types of plastics, including recycled materials.”

The company developed a standard range of systems, from small to extra large, which it will unveil at Moulding Expo on May 30 to June 2, 2017, in Stuttgart, Germany. Major equipment manufacturers in Europe and the United States will be testing the Ironjaw innovation over the next few months. The first industrial deliveries are announced for mid-2017.

“I chose to co-invest in Ironjaw because it is a technology with a lot of potential that addresses an international market,” said company co-founder Alex Guichard. “Bruno Machet is in charge of one of the sector’s most promising startups!”

source-:https://www.plasticstoday.com/injection-molding/ironjaw-boosts-injection-press-clamping-force/188907990656839