On its Sensitive Surface Days in February ENGEL once again demonstrated that it is a world’s leader when it comes to intelligent electronic plastic products with high-quality surfaces. Plastic processors from Australia and Japan even travelled to Austria to spend two days learning about how innovative technologies could be used to operate plastic surfaces with electronic intelligence. The event was attended by more than 140 participants.

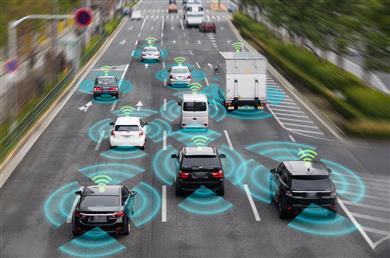

Gentle touches and direct interaction allow sensitive surfaces to dissolve the boundaries between drivers, vehicles, and smartphones in the automotive sector. Intelligent plastic surfaces, which are replacing mechanical buttons, sliders, and control dials with the help of capacitive electronics, are now being paid plenty of attention in other sectors too, however. Besides car suppliers, the Sensitive Surface Days were mainly attended by companies from the teletronics, white goods, and medical technology industries, and the event offered them an interesting mix of theory and practical experience.

The presentations covered path-breaking production technologies, market potential, and visions, among other things, before the participants were given the opportunity to watch a production cell in operation live.

The interface between man and machine revolutionised

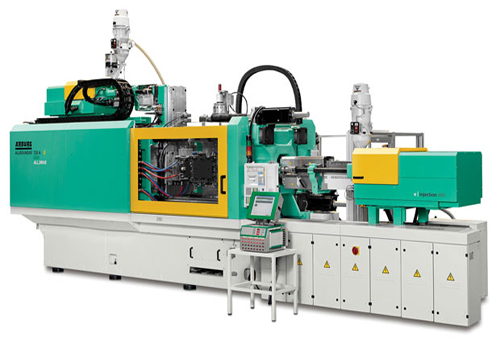

On an ENGEL duo 2050/350 pico injection moulding machine automated with an ENGEL viper 12 and an ENGEL viper 20 linear robot, installation-ready centre consoles for cars were made in just one work step using the ENGEL clearmelt method after starting with capacitive sheets. The pre-moulded three-dimensional sheets were inserted into the mould by the ENGEL viper 12 robot, overmoulded with a thermoplastic, and then flow-coated with polyurethane. The transparent polyurethane top layer makes the surfaces extremely durable and also gives them a classy appearance.

“Sensitive surface technology revolutionises the interface between man and machine”, says Michael Fischer, ENGEL AUSTRIA’s Technology Sales Director. “The integrated production process opens up completely new liberties to product designers and significantly reduces manufacturing costs at the same time. The centre consoles presented, for example, cost 30% less to make using this new method. Since no assembly is required, productivity is increased sharply too.”

Networks – a key to success

The exchange of information and intensive networking among the participants was also very important to the initiators of the first Sensitive Surface Days at ENGEL’s premises. “Sensitive surface projects require lots of different expertise,” says Michael Fischer. “In this dynamic growth market we can only be successful in the long term if we work closely with other companies who are leaders in their field.” The partners who hosted the event with ENGEL were Magna Exteriors & Interiors, plastic electronic, formquadrat, Schöfer, Hennecke, and Votteler.

Source: http://www.engelglobal.com/engel_web/global/en/22_4454.htm