The plastics supplier and the manufacturer of injection molding machinery announced they will install and run an injection molding cell during

The plastics supplier and the manufacturer of injection molding machinery announced they will install and run an injection molding cell during

next month’s Fakuma trade show to illustrate for plastics processors measures for increasing energy efficiency in injection molding throughout the entire value chain, from pellet to part. Using a specially-optimized grade of BASF’s plastic and the appropriate machine technology, the two companies will demonstrate how new developments can work together to reduce an injection molder’s energy bill.

The injection molding cell exhibit by BASF (Ludwigshafen) and Arburg (Lossburg, both Germany) will be part of a special show-within-a-show during Fakuma 2011 (Friedrichshafen, Germany; Oct. 18-21). The show has a long history as a highlight on the trade show circuit for injection molders, mostly processors from Europe but increasingly also from overseas. It’s reputation among molding machine manufacturers is that of a show where molders come with concrete projects to discuss and investments to make.

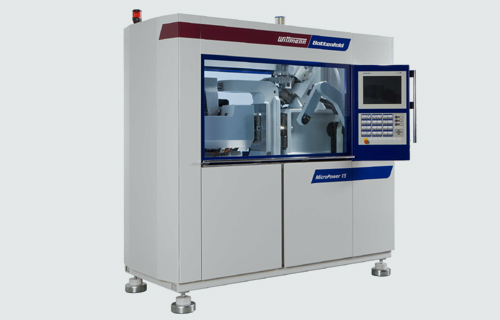

At Fakuma, on a total exhibition area of 100 m2, the two will install an injection molding cell to exhibit a cell to exhibit the entire injection molding process in terms of energy-efficiency: from product design through to production planning. Molding with two different plastics will show how energy efficiency can be enhanced by the right choice of material. For this purpose, an electric Allrounder 370 E molding machine from Arburg will form test parts from a standard plastic and from a material that was specially improved in terms of its flow characteristics. The “energy measurement” function built into Arburg’s Selogica machine control system registers the energy requirement of the relevant process.

The comparison, say the companies, will make clear how an energy-optimized machine, together with a plastic with improved flow characteristics, can contribute to significant energy savings in injection molding. The “energy saving” material will be BASF’s Ultramid B3WG6 High Speed grade, a polyamide 6 with 30% glass fiber reinforcement.

Not only can energy be saved by using a material with improved flow properties; better flow also makes it easier to fill complex cavities, of course, and means molders can use less injection pressure, subjecting molds to less wear. This increases operating times and reduces maintenance costs. Plus, fewer injection points or hot-runner nozzles are required on molds.

Trials by BASF have shown that the cycle time can be reduced by up to 30% due to the approximately 40°C colder processing temperatures required with its High Speed grades versus standard ones.

Arburg says the exhibit will impress on processors how its Edrive series, in this case the electric Allrounder 370 E, with that series of machines introduced earlier this year during Arburg’s annual Technology Days open house. As we reported then, the Edrive is Arburg’s answer to processors’ need for a machine that delivers the benefits of all-electric drive technology, but at an “attractive price” closer to comparable hydraulic machines.

Expect to pay about 20-30% more for an Edrive than one of the company’s hydraulic machines of the same clamp force and injection unit size, but with Edrive molding machines faster and more energy efficient, according to the company. On the Edrive, all of the main axes are fitted with all-electric servomotors, while secondary axes are optionally servo-electric or hydraulic. Depending on the application, energy savings during molding can be as high as 25 to 50% in comparison with standard hydraulic machines, says Arburg.

Source : www.plasticstoday.com