Responding to continuous demand for reliability and performance of industrial pumps, CREATEC GmbH & Co. KG has devised a revolutionary set of CREACOMP® PT (Pump Type) composite materials that combine VICTREX® PEEK polymer with carbon fibre. These composites have been successfully used to replace metals in the manufacture of parts subject to intense wear in pumps, resulting in enhanced process reliability, greater energy efficiency and a consequent cost savings.

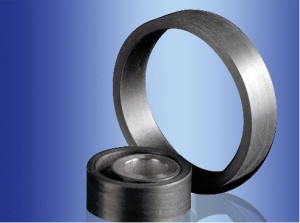

Most heavy industrial pumps are designed and fitted with sets of replaceable components subject to wear (e.g., bushings, case and impeller wear rings). These wear parts are designed to support and stabilise the pump rotor and offer protection to the shaft, impellers and pump casing by absorbing wear and abuse. In addition to these roles, wear rings act as internal seals and, to prevent frictional contact, maintain a gap between the impeller and pump casing. It is essential to keep this gap or clearance at an optimum value to improve efficiency.

Testing by CREATEC GmbH & Co. KG has revealed a significant gain in energy efficiency and cost savings when composite manufactured wear rings are used. The gain in efficiency of a typical multistage process pump is 4-5% when clearance is reduced by 50%. A test of an upgraded six-stage process pump revealed an improvement in efficiency from 82.5% to 87%, reducing the cost of electrical power consumption by EUR 80,000 per year. As a result, pump manufacturers are increasingly using VICTREX PEEK polymer-based thermoplastic composites such as CREACOMP® PT for wear part components to improve efficiency and save energy costs.

VICTREX PEEK (Poly-Ether-Ether-Ketone), from Victrex Polymer Solutions, the leading manufacturer of high performance polyaryletherketones and a major supplier of thermoplastics to the composites industry, is a linear semi-crystalline aromatic polymer, widely regarded as the highest performing thermoplastic material currently available. VICTREX PEEK polymer has excellent frictional and wear properties, with superior resistance to a wide range of aggressive chemical environments.

Traditionally, bushings and wear rings have been made from metallic materials such as Bronze, Stainless Steel and cast iron, but today CREACOMP® PT thermoplastic reinforced VICTREX PEEK polymer-based composite materials, available in four grades, can now be used as a metal replacement. Additionally, these thermoplastic composites cover applications that traditional materials were not suitable for. With excellent strength and wear, minimised running clearances are possible as a result of the non-galling and non-seising nature of these composites.

Victrex Polymer Solutions helps customers and end users achieve the greatest possible benefit from the use of its high performance materials to achieve cost effective, reliable solutions for long-life applications of today and in the future. All of this, backed by more than 30 years of experience, makes Victrex the only company in the world that can offer this level of specialised support. Victrex Polymer Solutions is the sole manufacturer and supplier of VICTREX PEEK polymer worldwide. For more information, please visit the Victrex website at www.victrex.com.