Hekuma GmbH, a manufacturer of automation solutions for injection molding systems, headquartered in Eching near Munich,

is represented with a comprehensive product presentation at the K2010, the world’s largest plastics and rubber trade fair to be held this year from October 27 to November 3 in Düesseldorf, Germany.

The Hekuma stand provides an overview of the comprehensive range of services for high performance manipulation and processing of injection molded parts.

Two new exhibition novelties will be presented as exhibits:

Concept-system with new solutions for increase in quality and productivity

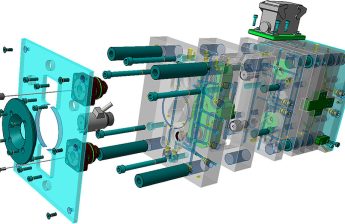

The automation system demonstrates new ways to increase productivity in the currently still free-falling injected molded parts and how competitive advantages can be simultaneously achieved through by improving product quality. In addition it is demonstrated how a standardized system can be adapted to different production conditions.

The new HekuCell, an extremely compact and flexible applicable high performance and manipulation cell for combination with small to mid-size horizontal injection molding machines.

With a 6-axis articulated arm robot, designed for lateral part removal from the injection molding machine, it is an interesting entry option into the automatic part handling of fast cycling injection molding machines.

Originally designed for testing, developed for pilot and initial series production to qualify and optimize high performance molds, the HekuCell also offers in particular through its compact size advantages for special cases in standard injection molding, especially where production space is limited–both between machines as well as low ceiling clearances.

The Hekuma trade show presentation will be complimented with additional system examples at exhibition stands of partner companies.

1.) Petri Dish – Automation at the Engel Exhibition Stand

A high performance system for the removal, assembly, and packaging of 90 mm Petri dishes is to be seen in production at the exhibition stand of the injection molding machine manufacturer Engel. The basis lies in the production with an 8+8 cavity mold from Plastisud/France in cycle time of less than 4.5 seconds.

2.) Pipette Tips – Automation at the Fanuc Exhibition Stand

Another automation example for medical technology is the combination of a Fanuc injection molding machine and a high-speed system for removal, inspection, and packaging of 32 pipette tips in a mold open time of less than 0.45 seconds.

It will also be on display in production.

3.) In-Mold-labeling for Thermoforming: TSL Exhibition Stand

Another highlight scheduled is the demonstration of a high performance system IML automation in combination with a thermoforming system (T-IML) for packaging cups. The Hekuma T-IML–System demonstrated on the stand of the American thermoforming machine manufacturer TSL-Thermoforming Systems LLC, will be the first production plant in North America.

Source : www.adsalecprj.com