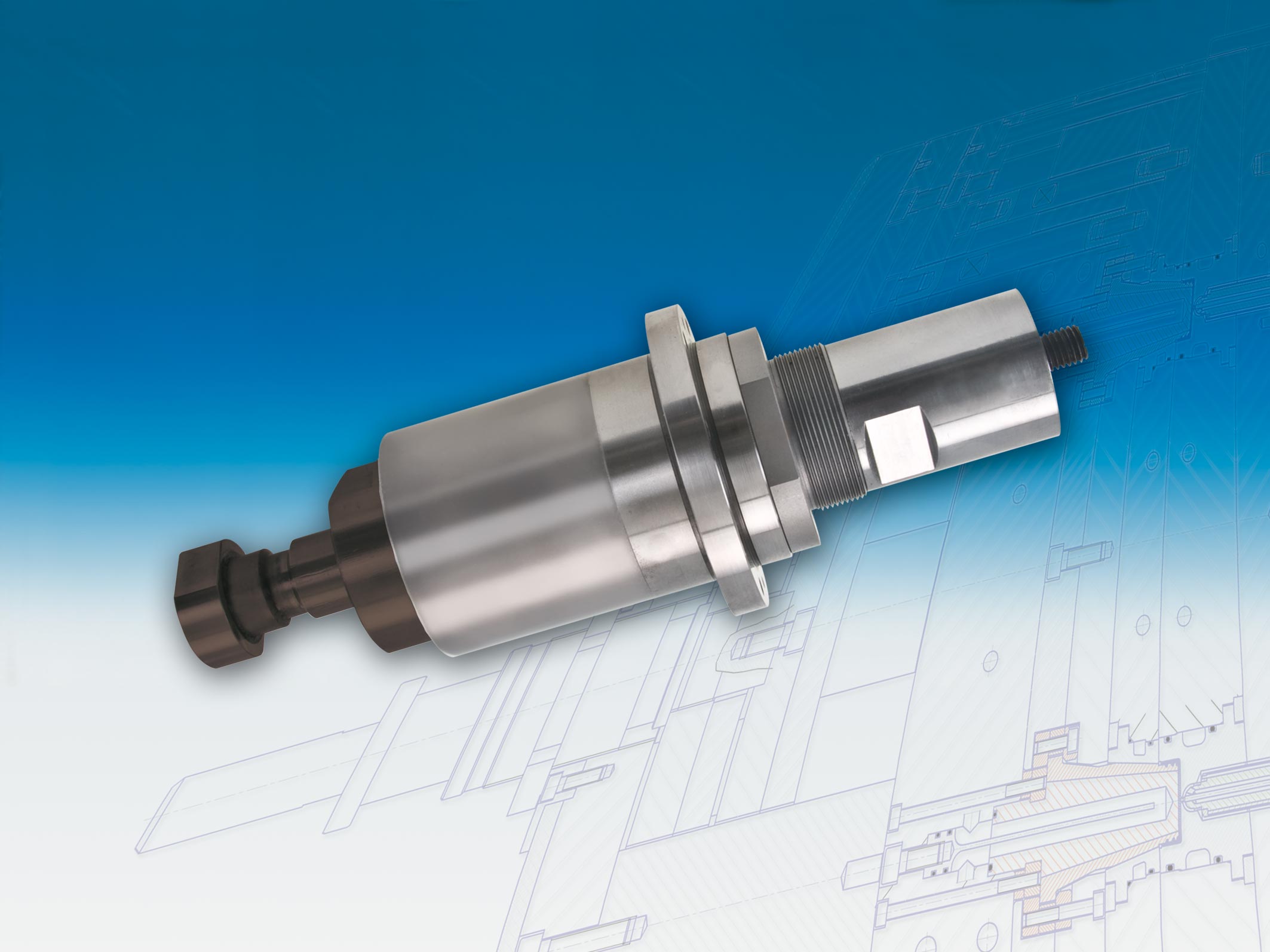

HASCO has introduced a new two-stage ejector, Z1692/…, which allows complex undercuts to be demolded on plastic articles.This seemingly straightforward mechanism, with its force-controlled and low-play movement, even permits the release of undercuts located inside the part.

A further use for two-stage ejectors is in molds incorporating a stripper plate, or for the separate demolding of the sprue and the article, said Germany-based HASCO Hasenclever GmbH + Co KG.

The company supplies the Z1692/… to implement special series sequences, such as those required for underground slides or inclined sliding carriage elements. These advancing two-stage ejectors, which are designed for central installation, make it possible to define the two strokes that are required completely independently of each other.

This independence, HASCO explained, is achieved because the stroke of the three standard sizes, with maximum stroke lengths of up to 180mm, can be adjusted by means of a simple modification.

The functional surfaces of all HASCO two-stage ejectors have a DLC coating to allow these products to be used in clean rooms and for the production of articles for medical technology and the food industry.

With its high hardness and good slip properties, the DLC layer helps to avoid abrasive and adhesive wear. This results in the required freedom from lubricant, which also directly reduces maintenance costs and downtime, added the company.

HASCO also supplies the two-stage ejector Z1692/… as a special, customized version with pre-set strokes.