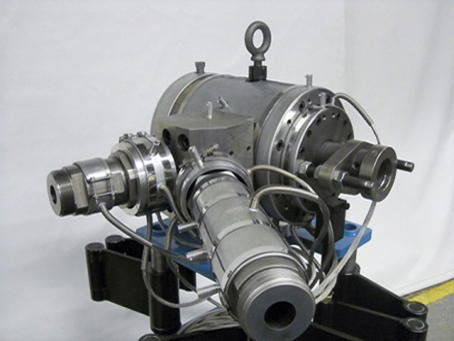

US-based Guill Tool has introduced Series 725, a co-extrusion crosshead design with all stainless steel construction for tray cable applications.

Series 725 was developed by Guill in partnership with its customer to convert a production line from a Tandem line with two heads a distance apart into a co-extrusion line with a single head applying both layers of polyvinyl chloride (PVC) in a single operation.

Featuring the patented Guill Seal Right system of self-aligning tapered deflector and body design, the efficiency of such configuration has improved substantially, according to Guill.

Other advantages include a shorter changeover time, less scrap with a single head setup, improved product quality from the increased adhesion between layers, as melt adheres to melt rather than extrudate, plus the inner layer is not exposed to the environment, allowing contaminates between the layers.

Additional features of this new crosshead include multi-port spiral flow, easy disassembly and restart, positive seals for leak elimination, adaptable to all extruder brands, maximum thru-core of 1.750″ and maximum die ID of 2.000″, first layer fixed and second adjustable, the patented Guill Feather Touch concentricity adjustment, vacuum port and the ability to accept two extruders from the same side via the heated manifold assembly.

Wbsite: www.adsalecprj.com