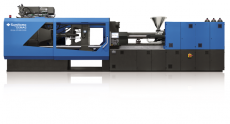

Schwaig, April 18, 2018 — With a market share exceeding 20 %, Sumitomo (SHI) Demag is the

leading manufacturer of injection moulding machinery for plastic packaging. Launched twenty

years ago, the hybrid El-Exis SP is the main contributor to this success. Now in its fourth

generation, it is the quickest and most advanced machine on the market.

Energy efficiency marks the fourth generation of the El-Exis SP

Located in Schwaig near Nuremberg, the injection moulding machine manufacturer has adapted the highspeed

machine from version to version to meet the increasingly exacting demands of packaging

producers. The fourth generation was introduced in 2016 and is primarily distinguished by its optimised

use of energy and resources — one of the most pressing challenges in engineering given the global

increase of production volumes. Depending on production parameters, it requires up to 20 % less energy

when compared to its predecessor. The hydraulic accumulator enables the achievement of injection

speeds of up to 1,000 mm/s and accelerations of up to 4g. Intelligent accumulator control simultaneously

ensures process-dependent, variable accumulator allocation.

Machine with clamping force of 8,000 kN broadens the spectrum

The hybrid concept combines the high speed demanded by the customer with availability and reliability in

a single machine — characteristics which are particularly indispensable during typical packaging

applications involving high quantities and a low part weight. “Right from the outset, development of the ElExis

focused on the demand that performance, service life and energy consumption should play equally

important roles and that no sacrifices should be made in this respect”, explained Arnaud Nomblot,

Director Business Development Packaging at Sumitomo (SHI) Demag. The dynamic hybrid drive ensures

a maximum level of performance and excellent process consistency and accuracy, both during

acceleration and braking. “In the area of packaging, we primarily benefit from two facts. First of these is

our specific experience in this sector, for example during the design of mould clamping plates which,

thanks to finite element analysis, exhibit considerably superior rigidity to conventional plates and,

secondly, the high vertical range of manufacturing in our company. Crucial machine elements such as

screws, plates or columns are manufactured by us rather than being purchased outside”, continues

Nomblot. “This direct control of manufacturing precision is a decisive factor in ensuring that the machine

meets all requirements in the high-speed range and works reliably and accurately over the years.”

Sumitomo (SHI) Demag now also meets the growing demand for large machinery for multiple cavities by

expanding the clamping force range of the El-Exis SP series. With maximum clamping forces of 8,000 kN,

the machine impresses through a dry cycle time of 2.05 seconds during daily operation. Cycle times of

less than 4 seconds for the production of milk product containers (500 gram) in an 8-cavity IML mould

underline the aspiration of the German-Japanese machine manufacturer to set the high-speed

benchmark on the market with the El-Exis SP.

Broad application spectrum as standard feature

Next to the ejection rate, repeatability, availability, efficiency and sustainability, versatility has since

become an equally important development driver. The El-Exis SP opens up a wide process window to the

user when it comes to cycle times and process parameters such as injection speed. IML, two-component

and injection compression moulding are also standard. Injection compression moulding in particular is

one of the technologies at Sumitomo (SHI) Demag that is suitable for more sustainable, higher quality

and, simultaneously, more cost-effective packaging production. A high precision level and the injection

speed of El-Exis SP machines transform injection compression moulding into speed compression, even in

the standard version. For example, trays made of a PP Mfi 20 with a flow path wall density ratio of 450:1

are produced in a cycle time of 3.5 seconds in a 2+2 cavity level mould developed and patented by

Plastisud. This technique achieves wall thicknesses up to 25 % thinner and, consequently, a lower part

weight with comparable product characteristics. In addition, the customer can run processes with around

30 % lower clamping forces.

Two-component injection moulding is also part of the standard repertoire of the El-Exis SP, which allows

applications such as the production of premium packaging with a high level of transparency, in-mould

labelling and superior-quality colouring. Injection moulding of buckets with an integrated handle is also

possible using the two-component process. This extremely rapid and stable process was standardised

and optimised together with Brink Werkzeuge. Thanks to maximum performance, large machines in the

El-Exis SP series are particularly suitable for the production of buckets that require higher clamping

forces.

Sumitomo (SHI) Demag Plastics Machinery GmbH

Sumitomo (SHI) Demag hat die Entwicklung der Kunststoffbranche seit Beginn an nachhaltig geprägt. Als

Spezialist für Spritzgießmaschinen zur Kunststoffverarbeitung gehört Sumitomo (SHI) Demag gemeinsam

mit seinem japanischen Mutterkonzern Sumitomo Heavy Industries zu den weltweit führenden

Unternehmen der Branche.

Das globale Entwicklungs- und Produktionsnetzwerk von Sumitomo Heavy Industries und Sumitomo

(SHI) Demag besteht aus vier Werken in Japan, Deutschland und China mit mehr als 3.000 Mitarbeitern.

Das Produktportfolio umfasst vollelektrisch und hybrid angetriebene Spritzgießmaschinen im

Schließkraftspektrum zwischen 180 und 20.000 kN. Mit über 115.000 installierten Maschinen ist

Sumitomo (SHI) Demag in allen wichtigen Märkten der Welt präsent.

Das Sumitomo-Stammwerk in Chiba, Japan stellt Maschinen mit kleinen und mittleren Schließkräften her.

Rund 95 % aller ausgelieferten Maschinen besitzen ein vollelektrisches Antriebskonzept. Mit mehr als

5.000 verkauften Maschinen pro Jahr gilt Sumitomo Heavy Industries mit ihrer

Kunststoffmaschinensparte als einer der größten globalen Hersteller von Spritzgießmaschinen.

Die deutschen Demag-Standorte in Schwaig und Wiehe fertigen mit hybridem Antriebskonzept die

Baureihe Systec Servo sowie die Hochleistungs- und Schnelllaufmaschinen El-Exis SP und Systec SP.

Die Baureihe IntElect mit elektrischer Antriebstechnik wird ebenfalls in Deutschland für den

internationalen Markt produziert.

In Ningbo/China ist Sumitomo (SHI) Demag bereits seit 1998 mit einer Produktion vor Ort. Seit Mitte 2015

verfügt das dortige Tochterunternehmen Demag Plastics Machinery (Ningbo) Co., Ltd. über ein neues

Werk mit 13.000 m² Nutzfläche, in dem die Serie Systec C mit 500 bis 10.000 kN Schließkraft für

asiatische Märkte gefertigt wird. Neben Spritzgießmaschinen bietet Sumitomo (SHI) Demag

kundenindividuelle und standardisierte Systeme zur Automatisierung des Formteilhandlings, verfahrensund

prozesstechnische Lösungen für Sonderanwendungen, maßgeschneiderte Dienstleistungen und

Servicekonzepte sowie Angebote zur Finanzierung der Investition in Spritzgießmaschinen.

Mit seinem lückenlosen Vertriebs- und Servicenetzwerk aus Tochtergesellschaften und Vertretungen ist

Sumitomo (SHI) Demag in allen wichtigen Industriemärkten präsent.

Contact

Amely Groner, Marketing Manager

Sumitomo (SHI) Demag Plastics Machinery GmbH

Tel.: +49 911 5061-5005

Email: amely.groner@dpg.com