Chinaplas 2014: RAMPF presents the new dispensing robot DR-CNC with live application of RAKU-PUR® Speed

Grafenberg, 02/24/2014. The international RAMPF Group will be presenting its innovative engineering and chemical solutions at the Chinaplas 2014 in Shanghai from March 23 to 26. At the RAMPF booth, the new dispensing robot DR-CNC from RAMPF Dosiertechnik will dispense the fast-curing soft integral foam RAKU-PUR® Speed from RAMPF Giessharze – a prime example of the Group’s ability to offer cutting-edge technologies and solutions from a single source.

Like many international companies, the German RAMPF Group considers the Chinese market to be one of the most important and dynamic worldwide. Since 2004, RAMPF has been selling the products of RAMPF Giessharze, a renowned developer and manufacturer of polyurethane and epoxy resin systems and silicones, in China.

Also since 2004, RAMPF has been marketing and selling the products of RAMPF Dosiertechnik, one of the leading manufacturers of low-pressure mixing and dispensing systems, via its partner Orient RAMPF Dosiertechnik. In 2007, the subsidiary RAMPF (Taicang) was founded in Taicang, a city which is about 50 kilometers from the center of Shanghai and has a population of 470,000. The company produces electro casting resins and foam gaskets formulated by RAMPF Giessharze as well as mineral cast machine beds from the German RAMPF company EPUCRET, a leading supplier of complete solutions for customized multi-axis systems.

Product. Machine. Process.

At Chinaplas 2014, the new dispensing robot DR-CNC from RAMPF Dosiertechnik will apply the fast-curing soft integral foam RAKU-PUR® Speed from RAMPF Giessharze live and on site – true to the principal of product, machine, process. This exemplifies RAMPF’s unique selling point: the Group is able to offer its customers around the globe cutting-edge technologies and solutions from a single source. “Our foreign subsidiaries and distribution partners fully comply with German standards. This ensures that wherever engineering and chemical solutions from RAMPF are produced and sold, the highest quality is guaranteed,” says Michael Rampf, CEO of the RAMPF Group.

DR-CNC: highest flexibility for dynamic sealing, casting, and bonding

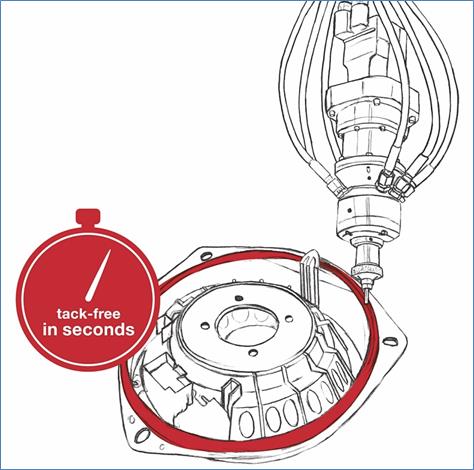

The dispensing robot DR-CNC from RAMPF Dosiertechnik is the ideal solution for complex applications. Variable X-Y-Z strokes enable the three-dimensional dispensing of sealants, adhesives, and encapsulants. The DR-CNC is equipped with the most advanced features in CNC technology to combine the mixing and dispensing system with a maintenance-free CNC linear axis. The modular architecture of the CNC allows for simple and full integration into existing production control systems.

Additional options include high-pressure rinse recycling system or high-pressure water rinsing system, nucleation controller for air load controls, material recirculation system and temperature controller, automatic thin-film degassing for bubble-free casting, various types of automation equipment, e.g. rotary index tables, shuttle tables, conveyor lines, and customized automation, as well as individual process monitoring and visualization amongst others.

RAMPF Holding GmbH & Co. KG

Albstrasse 37

D-72661 Grafenberg

T +49.71 23.93 42-1045

F +49.71 23.93 42-2045

E benjamin.schicker@rampf-

www.rampf-gruppe.de