To pay tribute to the emerging Wood-Plastic-Composites (WPC) market in India, battenfeld-cincinnati Austria, Vienna, has now enlarged its presence in this market by establishing a strategic alliance with Hardy Smith, Gujarat, India. The WPC extrusion equipment pioneer and the turnkey project specialist of the Indian wood industry are joining forces to offer their local customers ideal solutions for manufacturing innovative WPC products.

In India, WPC profiles and panels are emerging as a popular alternative to wood panels, which are generally scarce and often rather expensive, due to limited wood resources. Hardy Smith, originally a company of the wood industry, has already been engaged in the WPC project consulting business since 2011. Hardy Smith offers complete solutions for WPC manufacturing from concept to end product – followed by marketing support.

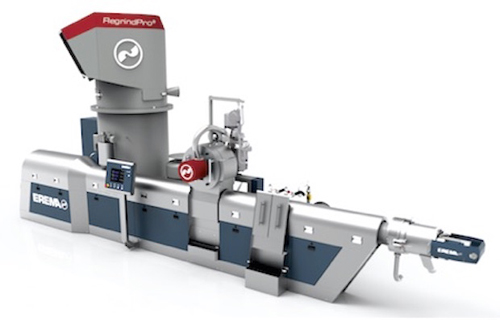

battenfeld-cincinnati has been offering custom-built extrusion machinery to manufacture WPC products for more than a decade. With continuous opti-mization of the equipment and further development of the critical process steps, battenfeld-cincinnati meets the demand for high output and improve-ment in product quality. As a co-founder of the WPC Platform Austria, the company has also become involved in the government funded COIN pro-ject, in which nine Austrian companies are pursuing the common goal of improving the mechanical attributes of WPC profiles by another 25 % and simultaneously achieving a 25% reduction in material costs.

At the WPC conference in Vienna, which was organized by AMI in spring this year, battenfeld-cincinnati presented its new fiberEX114 high-performance twin-screw extruder, which is setting benchmarks in terms of wear protection, output and melt homogeneity. To complete its product range, the machine manufacturer has now gone a step further and devel-oped a fiberEX93 as well. This extruder with a 34 D processing length closes the gap in the product portfolio and is suitable for profiles with weights per meter ranging from 2.5 to 3.5 kg/m resulting in extrusion speeds of up to 3-4 m/min.