The Chery taxi featured in a DuPont (Wilmington, DE) mini-documentary illustrating the benefits of lightweighting uses several engineering plastics, including Zytel nylon resin and Vamac ethylene acrylic elastomer in components ranging from the air-intake manifold and cylinder head cover to air ducts. Together, the components account for about a 30-40% decrease in component weight compared with their metal counterparts, generating a significant increase in fuel economy and reduction in CO2 emissions.

“The need to continue the drive to improve the sustainability of vehicles to meet mobility needs continues to drive innovation in the automotive industry,” said James Hay, regional director, Asia Pacific, DuPont Performance Polymers. “Working closely with customers helps ensure we develop advanced material solutions that deliver more sustainable solutions without compromising performance, safety or cost.” The DuPont video features Cao Tieniu, who drives a Chery taxi in Wuhu, China. “Compared to some cars, it uses less fuel,” he said. “For those of us who drive taxis, it increases our profits.” For Tieniu, that translates to more time with his family.

“Lightweighting technology is a very important component in the process of fuel efficiency,” said Chen Anning, vice president, Chery Automobile. “There has been a lot of cooperation between DuPont and Chery.” Chery has a long history with DuPont working with the teams in the China R&D center and around the world to develop lightweight components throughout the vehicles, but especially in engine components and systems. “Components surrounding the engine need to be resistant to high temperatures,” said Charlie Huang, business director, DuPont Performance Polymers, Greater China. “This is where engineering polymers can demonstrate their power.” Currently, the business is collaborating with Chery on developing plastic oil pans for several new engines which have high market potentials.

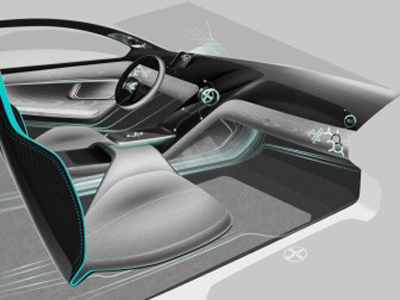

“Together we established the Chery-DuPont Joint Laboratory of New Materials Technology and Application Development in August 2010. It is an important platform for sharing new technologies and products and demonstrating development results,” said Anning. “The collaboration focuses on light weighting, new energy vehicles, interior and exterior accessories, advanced coating process, etc. Chery is committed to the development of hybrid vehicles, electric vehicles, new environmentally friendly materials, and new processes.”