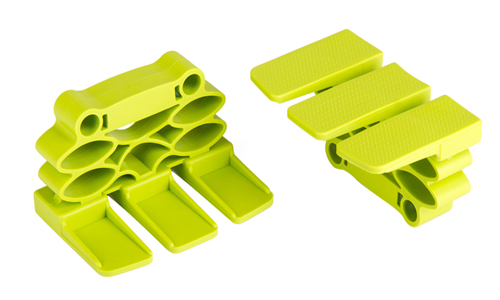

A Case Western Reserve University researcher has built a prototype wind turbine blade that is lighter and tougher than current ones using

A Case Western Reserve University researcher has built a prototype wind turbine blade that is lighter and tougher than current ones using

carbon nanotube reinforced polyurethane, according to the university’s press release on August 30.

Marcio Loos, a post-doctoral researcher in the Department of Macromolecular Science and Engineering, co-operates with colleagues at Case Western Reserve, investigators from Bayer MaterialScience in Pittsburgh and Molded Fiber Glass Co. in Ashtabula, Ohio, the US, comparing the properties of new materials with the current standards used in blade manufacturing.

On her own, Ms Loos built a polyurethane blade reinforced with carbon nanotubes, which the university claimed to be the world’s first. Using a small commercial blade as a template, he manufactured a 29″ blade that is lighter, more rigid and tougher.

“The idea behind all this is the need to develop stronger and lighter materials which will enable manufacturing of blades for larger rotors,” Ms Loos said.

“Results of mechanical testing for the carbon nanotube reinforced polyurethane show that this material outperforms the currently used resins for wind blades applications,” said Ica Manas-Zloczower, Professor of Macromolecular Science and Engineering and Associate Dean in the Case School of Engineering. Ms Loos is working in the Manas-Zloczower lab where she and Chemical Engineering Professor Donald L. Feke, a Vice Provost at the university, serve as advisors on the project.

In a comparison of existing reinforcing materials, the researchers found carbon nanotubes are lighter per unit of volume than carbon fiber and aluminum and had more than 5 times the tensile strength of carbon fiber and more than 60 times that of aluminum, as said in the press release. Fatigue testing showed the reinforced polyurethane composite lasts about eight times longer than epoxy reinforced with fiberglass. The new material was also about eight times tougher in delamination fracture tests.

As said, the performance of polyurethane composite in each test was even better when compared to vinyl ester reinforced with fiberglass, another material used to make blades. The new composite also has shown fracture growth rates at a fraction of the rates found for traditional epoxy and vinyl ester composites.

Ms Loos and the rest of the team are continuing to test for the optimal conditions for the stable dispersion of nanotubes, the best distribution within the polyurethane and methods to make that happen. Manas-Zloczower concluded, “They will be used to emphasize the significant potential of carbon nanotube reinforced polyurethane systems for use in the next generation of wind turbine blades.”

The research is funded by a US Department of Energy stimulus grant and Bayer MaterialScience.

Source : www.adsalecprj.com