BOY, a German specialist of micro injection molding machinery, will introduce itself at K2010 with the new slogan –

“Great Machines – compactly designed”. BOY will display sixteen machines during the exhibition.

Nine newly launched BOY XS series machines will be introduced at K2010. These machines can produce micro and small parts with injection volumes between 0,1 and 8,0 cm³ in a completely automatic, precise and highly efficient way. The BOY XS is available as a horizontal machine and as a vertically configured insert molding machine. The space requirement is only 0,8 or 0,6 m².

The BOY XS machine, which comes standard with the Procan ALPHA control system, is as compact as a table machine, but has all the functionality of bigger machines. It is designed and built for 24/7 production environments. The BOY XS offers all the economical advantages that come with one-mold devices instead of bigger machines with multiple molds devices. During K2010, the BOY XS will introduce itself as an ultra compact multi-functional machine capable of running many interesting applications.

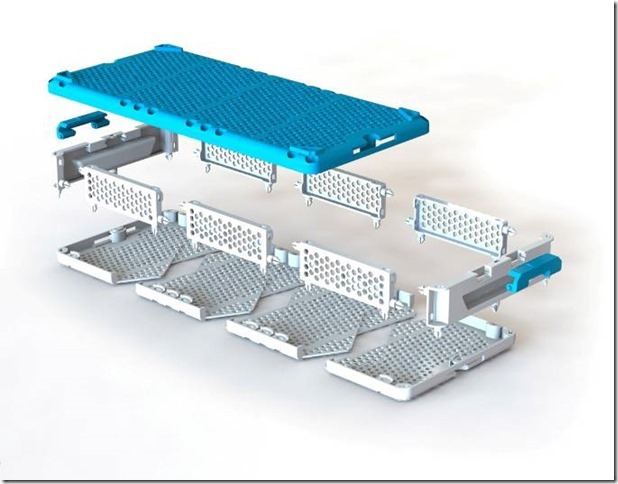

As shown, the BOY XS is designed to allow the integration of peripheral devices and handling equipment without the requirement of additional floor space including such devices used for drying, conveying and coloring. A new control device on the BOY XS also allows the placement and removal of parts.

The BOY XS cleanroom application is very different from traditional types. The automatic injection molding machine, completely suitable for cleanroom applications, assures the production of parts according to ISO 14644-1 (class 6/1000) cleanroom standards. Micro-parts from biomedical engineering with injection volumes under 0,1 cm³ will be produced with sprueless injection.

The versatility of the BOY XS is clearly demonstrated by its ability to process many different materials including thermoplastics, thermosets, elastomers, liquid silicone rubber (LSR), MIM (metal injection molding), PEEK, and hot melt.

Another focus for BOY during K2010 are the BOY E-series machines. These machines have a much lower energy requirement, are highly precise, and are very dynamic and quick. Noise levels are greatly reduced.

The production of thermoset parts will be demonstrated on a BOY 22 A (220 kN clamping force). The BOY 22 A, a very mature product and almost unchanged, has been present for decades in the BOY production program.

BOY also specializes in the production of vertically configured insert molding machines. During the exhibition, the BOY XS V and BOY 35 VV machines will demonstrate interesting insert molding applications. A major feature is the fixed lower platen, which eliminates the movement of parts during the closing cycle. Other advantages are the free accessibility to the mold and the possibility of placing automation equipment on the machine frame thereby greatly reducing the need for additional floor space.

Source : www.adsalecprj.com