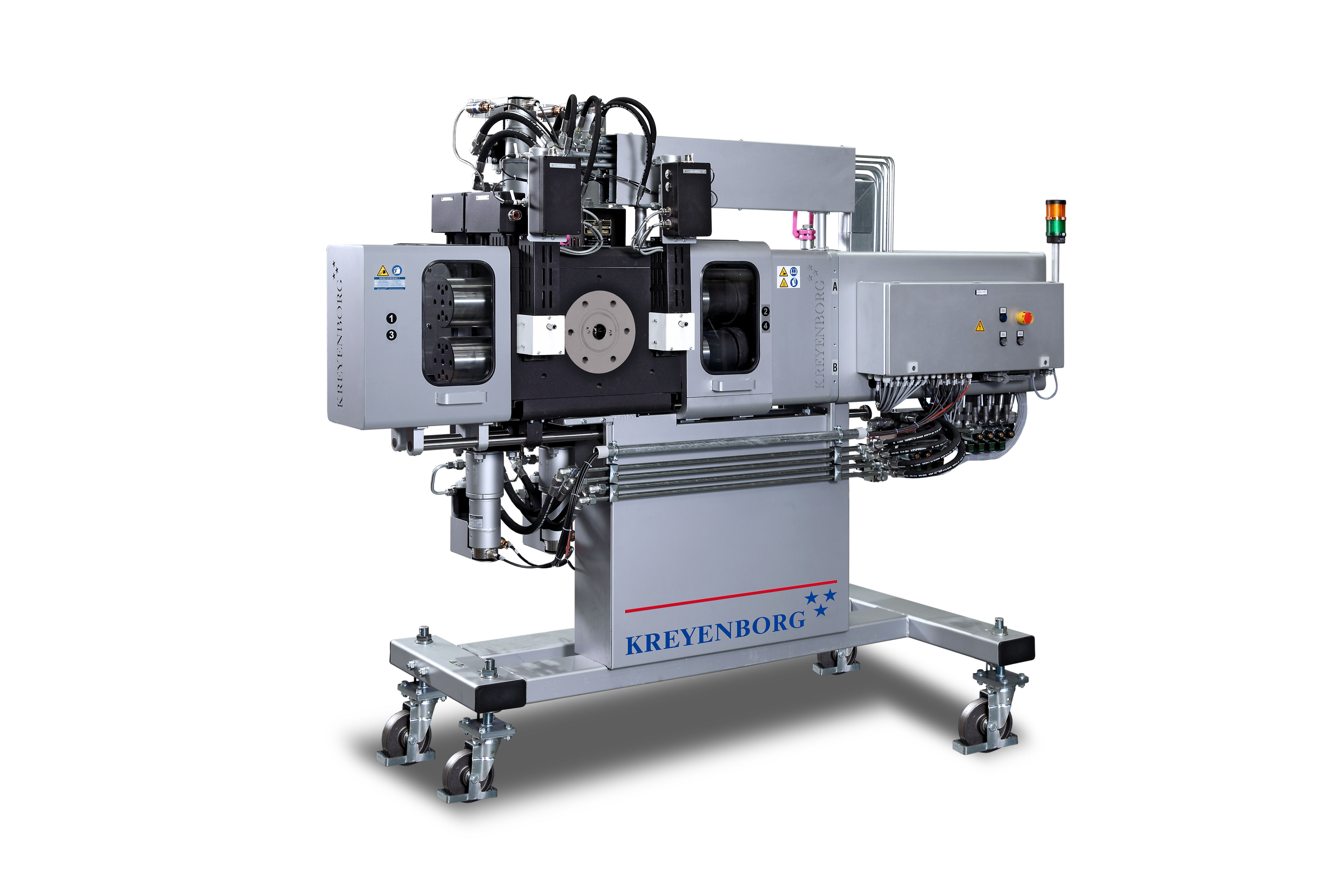

Extrusion machinery manufacturer Boston Matthews announced the launch of the ProCat range of Caterpillar Haul-Off machines.

The ProCat range is designed to pull larger profiles and pipes which require more power and product contact than “standard” sized profiles and pipe haul-offs.

Larger construction with longer conveyors

As introduced, a robust and heavy weight construction ensures stable, vibration free pulling even for products which require high levels of vacuum during the extrusion process. The larger construction incorporates longer conveyors to maximize the overall contact length with the product to provide greater pulling efficiency and overall consistency.

The conveyors are driven and controlled by dual high performance AC brushless motors and precision gearboxes utilizing high resolution Encoder Feedback. A high level of torque is generated whilst maintaining consistent pulling speeds which are essential for high quality production. AC technology is not only more accurate but is also more energy efficient than DC alternatives, the company explained.

Each conveyor is fitted with Grooved Rubber gripping pads to ensure maximum grip on the product without causing damage or distortion. A choice of conveyor coverings is available to exactly match the product characteristics or production environment.

More protection by flexible top track

A Floating Air Top Track greatly assists with line start-up and also provides protection against machine damage should any ‘out of shape’ pipe or profile be produced. The flexible top track enables the ProCat to ‘absorb’ any inconsistencies in the product should they occur and thus reduce any negative impact it may have on the performance of the rest of the extrusion line. The Pneumatic Air Top positioning is also a feature to allow the operator to easily and repeatedly set the ProCat up ensuring consistent production performance

Adjustable product in-let guides ensure the profile or pipe is correctly positioned in-line to enable the maximum contact is achieved. Tunnel in-let and out-let guides provide complete operator safety. The ProCat is fully guarded and CE marked.

Boston Matthews Technical Sales Director Simon Brookes stated: “The importance of the Caterpillar Haul-Off should never be underestimated and its performance is instrumental to the overall quality of any extrusion operation. As the originators of the Caterpillar Haul-Off we understand that without repeatable, accurate and consistent pulling of the extrudate, all other operations in the extrusion line are affected and the quality of the finished product put into jeopardy.”

The ProCat forms part of a range of Caterpillar Haul-Off machines which have been designed specifically to meet the exact pulling requirements and characteristic of the product and production environment.

Website: www.adsalecprj.com