An Expert Forum will be held in parallel with parts2clean 2014, an international trade fair for industrial parts and surface cleaning in Stuttgart, Germany from June 24-26, announced the show organizer, Deutsche Messe.

“The Fraunhofer Cleaning Technology Alliance is responsible for technical coordination of the program, which covers various areas of cleaning technology,” reports Olaf Daebler, Director of parts2clean at Deutsche Messe. “A total of 30 speakers will be giving presentations on everything from the basics to specialist issues.”

All presentations will be simultaneously interpreted (German <> English).

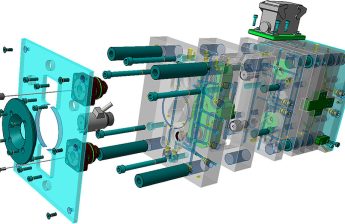

The four presentations in the first session on June 24 focus on the topic of “Process and engineering knowledge”. This includes presentations on knowledge-based process control in industrial parts cleaning, the selection and positioning of nozzles for spray cleaning, the performance range of modified alcohols and the design of workpiece carriers for individually positioned parts.

The afternoon program is organized by the Fachverband industrielle Teilereinigung e.V. (FiT) and features the Quality Podium. This includes five presentations on process chain analysis as an approach for avoiding errors, with possible solutions being shown and best-practice applications presented. The session concludes with a podium discussion of the topic: “Knowledge transfer and competence – supply and demand”.

On the second day of the trade fair, the morning session focuses on cleaning processes, pre-treatment and coating. Topics addressed include current trends in precision cleaning with ultrasound and potential applications for laser beam cleaning in the automotive and motor vehicle industry.

Entitled “Needs-based deburring with the right process”, the afternoon session will see speakers present a variety of deburring solutions as well as their possibilities and limitations.

On the third day, the Expert Forum begins with a series of presentations on the maintenance and preparation of cleaning baths. The program includes presentations on avoiding component waste through efficient wash water treatment and on measured value surface tension for the control and management of the surfactant effect in parts cleaning.

The afternoon session looks at methods for particle contamination, with presentations on a variety of topics, including systematic manufacturing analysis in order to reduce waste due to contamination, real-time measurement of particle agglomeration on surfaces, and VDA 19, the set of regulations on checking technical cleanliness, the new edition of which is in the final stages of completion.