The organizing committee for the SPE Automotive Composites Conference & Exhibition (ACCE) has announced the three Best Paper Award winners for the group’s 13th annual show, to be held from September 11-13 in Detroit, the US.

All three winners come from the Virtual Prototyping & Testing of Composites technical session. They are Thierry Malo, Engineering Services Team Leader at e-Xstream engineering, an MSC Company; David Sheridan, Senior Design Engineer at Ticona Engineering Polymers, the engineering polymers business of Celanese Corporation; and Dr. Ivor Huan-Chang Tseng, Program Manager at CoreTech System (Moldex3D) Co. Ltd.

Thierry Malo is lead author, along with Laurent Adam and Roger Assaker, also of e-Xstream engineering, and Tsukatada Matsumoto and Riccardo Giacomini from Toyota Motor Europe, on a paper entitled Multi-Scale Modeling of High Cycle Fatigue of Chopped and Continuous Fiber Composites.

The paper introduces two micro-mechanically based composite fatigue models. The focus is on the high-cycle fatigue model implemented specifically for chopped-fiber-reinforced plastics that were used on an automotive oil-cooler bracket for a Toyota vehicle in Europe. The bracket is molded from short-glass reinforced polyamide (PA) 6/6 resin.

Through this case study, the presentation on September 12 will show how the use of proper fatigue-modeling tools, developed specifically for composites, can increase the accuracy of simulation in the field of durability and pave the way for new simulation standards that help support the desired weight reductions of vehicle components.

Meanwhile, David Sheridan is lead author, along with Ulrich Mohr-Matuschek and Anton Grzeschik of Ticona GmbH and Roland Peter of Inteva Roof Systems on a paper entitled Integrated Anisotropic Simulation for Components Made from Glass Fiber Reinforced Thermoplastics.

The paper discusses how accurately analyzing and predicting the mechanical behavior of components made from fiber reinforced thermoplastics is complex owing to the fact that fibers are individually oriented during injection molding. Finite-element analysis often uses isotropic material models, but accuracy of results can be improved if local fiber orientations are considered with anisotropic material properties. The presentation on September 12 will introduce the analysis process and a practical application.

Dr. Ivor Huan-Chang Tseng is lead author along with Yuan-Jung Chang, Tzu-Chang Wang, and Chia-Hsiang Hsu of CoreTech System (Moldex3D) Co. Ltd. and Rong-Yeu Chang, National Tsing-Hua University, on a paper entitled Three Dimensional Predictions of Fiber Orientation for Injection Molding of Long Fiber Reinforced Thermoplastics.

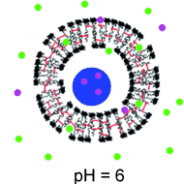

The paper discusses a recently proposed new fiber orientation model for improving the previously developed models for long fiber reinforced thermoplastic (LFRT) composites with regard to interaction and diffusion of the fibers immersed in a matrix. This improved Anisotropic Rotary Diffusion model combined with Retarding Principal Rate (iARD-RPR) model has been demonstrated to describe changes in fiber orientations well, whether treating short fibers or long fibers.

This was demonstrated in a study using 40 wt% glass-fiber immersed in a polypropylene (PP) matrix that was injection molded in a center-gated disk. Good correlation was achieved between predicted fiber orientation distribution through the thickness and experimental results. The paper will be presented on September 11.

Source: www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-67007512/Article.aspx