- Outstanding: Theses by Dr André Hemmler and Dario Pasquale Arcuti

- Groundbreaking: New findings in the field of prostheses

- Committed: Arburg honours dissertations and master’s theses from the Technical University of Munich (TUM)

This year again saw two graduates of the Technical University of Munich (TUM) awarded the Arburg Prize for outstanding theses in the field of plastics and medical technology: Dr André Hemmler for the best dissertation and Dario Pasquale Arcuti for the best master’s thesis. In both cases, the topic was the use of medical prostheses. The awards were presented by Prof Birgit Vogel-Heuser, holder of the Chair in Automation and Information Systems at the Technical University of Munich, and Arburg Training Director Michael Vieth.

Since 2016, Arburg has been working with the Technical University of Munich to honour two graduates each year for their outstanding dissertation or master’s thesis. The candidates are nominated by professors from the faculties of plastics technology, medical technology, and related scientific fields. “The aim of the Arburg Prize is to further advance research in plastics and medical technology”, said Michael Vieth. “I am always impressed by the exciting topics and pioneering research results.” Mr Vieth joined Dr Birgit Vogel-Heuser in Munich to present the Arburg prizes to winners Dr André Hemmler and Dario Pasquale Arcuti. Due to coronavirus, the award ceremony did not take place as usual as part of the open day of the Faculty of Mechanical Engineering at TUM, but in a small, personal setting.

Best dissertation: Predicting abdominal aortic aneurysms

In his paper, Dr André Hemmler developed numerical methods and simulation models to predict the outcome of endovascular treatment of abdominal aortic aneurysms. He validated these models with the aid of patient-specific data by comparing the simulation results qualitatively and quantitatively with real postoperative CT data. Based on the validated methods and models, he gave specific examples of how they can be applied in everyday clinical practice. These applications include the predictive estimation of the probability of complications based on mechanical and geometric parameters. The newly developed models also make the process of selecting a stent graft from the portfolio of commercially available stent prosthesis systems more objective and efficient, and enable the optimal stent graft diameter for the individual patient to be selected, something which is otherwise difficult to assess. In addition, a numerical proof of concept demonstrates the benefit of highly individualised stent grafts in patients with challenging aortic morphologies. “All in all, this paper contains important steps on the way to the use of simulation-based EVAR models in everyday clinical practice”, Dr André Hemmler stated in conclusion.

Best master’s thesis: Development of a venous valve prosthesis

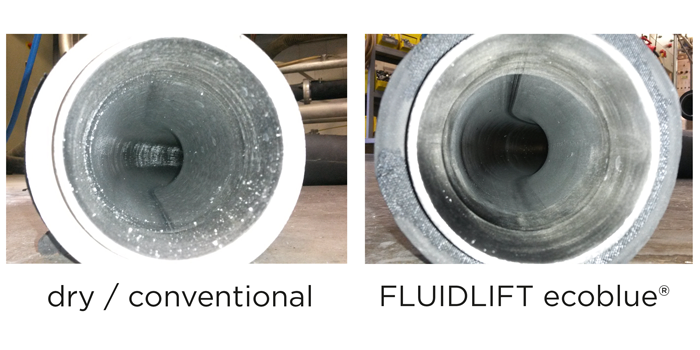

In his master’s thesis, Dario Pasquale Arcuti dealt with the development of a polymer-based venous valve prosthesis. The aim of his paper was to establish a process chain for the production of venous valves from thermoplastic polyurethane (TPU) by means of electrospinning. Electrospinning is a production method for the manufacture of continuous fibres into a non-woven material. Dario Pasquale Arcuti developed a computer-assisted model of the venous valve for the creation of the venous valve mould. He also established the process of mould production and

preparation using rapid manufacturing technology. He then evaluated the manufactured valve prototypes from various aspects. Among other things, the fluid dynamic properties of the valve were evaluated and the microstructure investigated. “My master’s thesis provides an initial approach for the development of a venous valve prosthesis at the Chair of Medical Engineering Materials and Implants”, stated Dario Pasquale Arcuti.

Press release

File: ARBURG Press release ARBURG prizes TU Muenchen2021_en_GB.doc

Characters: 3,672

Words: 551

This and other press releases are available for download from our website at www.arburg.com/de/presse/ (www.arburg.com/en/press/)

Contact

ARBURG GmbH + Co KG

Press office

Susanne Palm

Dr Bettina Keck

Postfach 1109

72286 Lossburg

Tel.: +49 (0)7446 33-3463

Tel.: +49 (0)7446 33-3259

About Arburg

German family-owned company Arburg is one of the world’s leading manufacturers of plastic processing machines. Its product portfolio encompasses Allrounder injection moulding machines with clamping forces of between 125 and 6,500 kN, the Freeformer for industrial additive manufacturing and robotic systems, customer and industry-specific turnkey solutions and further peripheral equipment.

Arburg is a pioneer in the plastics industry when it comes to production efficiency, digitalisation, and sustainability. The “arburgXworld” program comprises all digital products and services and is also the name of the customer portal. The company’s strategies regarding the efficient use of resources and circular economy, as well as all related aspects and activities, are outlined in the “arburgGREENworld” program.

Arburg’s central aim is for customers to be able to produce their plastic products, from one-off parts to large-volume batches, in optimum quality at minimum unit costs. The target groups include, for example, the automotive and packaging industries, communication and entertainment electronics, medical technology and the white goods sector.

An international sales and service network ensures first-class customer support at a local level: Arburg has its own organisations at 35 locations in 26 different countries and, together with its trading partners, is represented in more than 100 countries. Its machines are produced exclusively at the company’s German headquarters in Lossburg. Of a total workforce of over 3,300, approximately 2,750 people are employed in Germany. Over 550 people work in Arburg organisations around the world. Arburg has triple certification, in accordance with ISO 9001 (quality), ISO 14001 (environment) and ISO 50001 (energy).

Further information about Arburg can be found at www.arburg.com