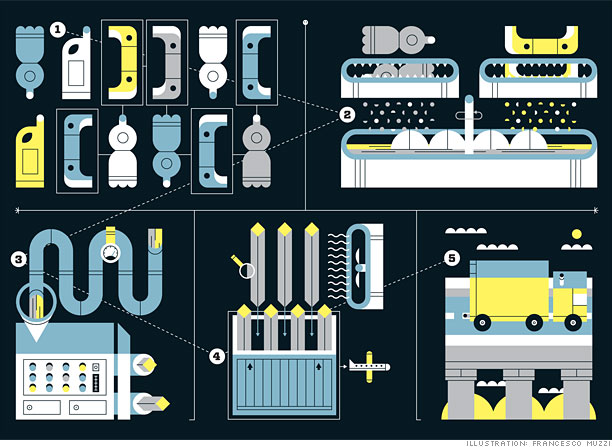

This month, we told you about a Lux Research report on the future of 3D printing and additive manufacturing (AM). That report said business relationships among AM machine makers and users will need to change as large manufacturers bring these technologies in-house and work to increase control over materials and processes.

We also speculated about whether some manufacturers with specialized needs might bring 3D printing and other AM techniques under their control by outright acquisition, investment, or other types of monetary support. We’re still waiting on that, but the aircraft engine maker Pratt & Whitney has opened a lab at the University of Connecticut that will use two different technologies to advance R&D for AM processes that produce metals.

Tom Prete, vice president of engineering for Pratt & Whitney, told us in an email that the lab will use electron beam melting (EBM) machines from Arcam and laser sintering from EOS. Pratt & Whitney is already using AM for prototyping for various engines, including its PurePower engines. Components have been made and engine-tested and are being certified for the PurePower engine family.

The Pratt & Whitney Additive Manufacturing Innovation Center will focus on fundamental R&D in manufacturing and materials science and will be able to produce prototypes, he said.

- The facility will be used to help accelerate development of cutting-edge additive manufacturing technologies. Some of these R&D activities include process development, materials development, and post-process development.

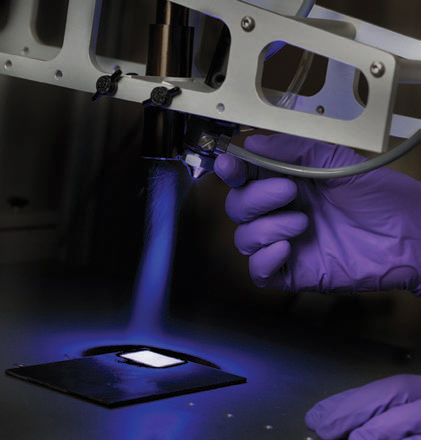

AM will “enable new, innovative designs with better performance and lighter weight that can’t be made through conventional methods.” The center is working with nickel and titanium alloys and plans to bring in other materials as the need arises.According to a brochure we received about the center, it will use two EBM A2X machines from Arcam and an EOSINT M270 laser sintering system from EOS. The EOS systems are for making tooling inserts, prototype parts, and end products in metal. The Arcam machines will be used to manufacture large, complex parts from a variety of metals that must be processed at high temperatures.

A CNC wire electrical discharge machining system will handle post-processing tasks such as removing parts from the build plate and finishing machining.Arcam says on its website that its A2 and A2X machines are designed specifically for the aerospace industry. Its EBM process produces components that have better material properties than cast metal parts and are comparable to wrought metal parts, because the high-temperature process occurs in a controlled vacuum.

The process uses multiple beams and melt pools to speed production. We’ve reported on other aerospace manufacturers using electron beam AM techniques, including Sciaky, which is building jet fighter wing boxes for Lockheed.Pratt & Whitney, whose headquarters are in Connecticut, said in a press release that it has invested more than $4.5 million in the center and plans to invest $3.5 million more by 2018. Prete said UTC (Pratt & Whitney’s parent) and the University of Connecticut are members of the National Additive Manufacturing Innovation Institute, and the company plans to submit proposals to the NAMII through the center.

Source: http://www.designnews.com/author.asp?section_id=1392&doc_id=262621&itc=dn_analysis_element&