Another nucleating executor for infusion shaped high-thickness polyethylene (HDPE) applications – Hyper form HPN 210 M, has been revealed by Milliken & Company. This new engineering gimmicks an interesting crystalline introduction that enhances the mechanical execution of HDPE to levels approaching those of polypropylene (PP) sway copolymers. Hyper form gives decays appealing new handling alternatives for bundling and material taking care of uses and underscores Milliken’s interest in progressing examination to profit clients around the world. The new added substance – which particularly targets material taking care of uses, for example, waste compartments, totes, cartons and beds – is the first in a group of cutting edge nucleates that Milliken is creating.

“Nucleating injection molded polyethylene has been an ongoing challenge throughout the industry that we’ve now addressed,” said Reed Walker, business development and marketing manager for Polyethylene Additives at Milliken. “With our new Hyperform HPN 210 M nucleating agent we are enabling injection molders to expand the performance space of high-density polyethylene and linear low-density polyethylene.” Delivering Multiple Benefits to Molders.

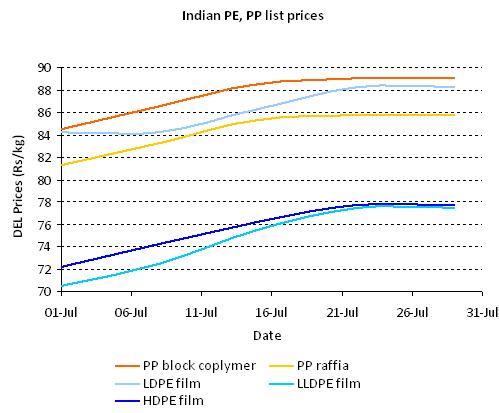

HDPE utilizing Hyperform offers decays of bundling and material taking care of items an interesting blending of profits. Testing done as indicated by the American Society for Testing Materials (ASTM D790-00) demonstrated expanded solidness (modulus) of up to 50 percent vs. standard HDPE. This solidness can empower more slender divider plans, helping weight diminishments of the last part. Moreover, Hyperform enhances HDPE’s high temperature safety, empowering it to be formed into an extensive variety of items where PP is as of now ordinarily utilized. HDPE with Hyperform helps heat bending temperatures by 10 – 40°c, as dictated by the ASTM D648-07 test.

Hyperform additionally enhances the handling advantages of HDPE, including higher gainfulness becausse of shorter cooling times. The new nucleator’s remarkable capacity to make lamellar precious stone introduction of PE in the polymer stream (or machine) course helps the decrease in shrinkage of polymer market in India. Control of shrinkage and warpage helps a change in the general nature of expansive, complex parts, opening the window for PE to turn into a potential material of decision in forms that generally run PP, without the need to re-device.

The new nucleating operator will be accessible in the United States on Dec. 1, and hence in Asia, Latin America and Europe, pending synthetic enlistments. Sustenance contact endorsements are likewise in methodology.