A significant quality improvement of the de-powdering and cleaning operation for 3D printed components at lower costs and shorter cycle times! A leading manufacturer of recreational vehicles is fulfilling this goal with the purchase of the automated post processing system S1 from AM Solutions – 3D post processing technology.

With their innovative designs and powerful drive systems the motor homes, caravans and panel trucks of the Knaus Tabbert AG allow safe, comfortable and sustainable travelling. At its German headquarters in Jandelsbrunn, Bavaria, the company is utilizing its comprehensive experience and knowhow to continuously improve the materials and designs of its vehicles. Naturally, this also includes the employment of new manufacturing technologies such as additive manufacturing (AM). Mario Meszaros, development engineer at Knaus Tabbert explains: „On the one hand we are using the 3D printing technology for creating prototypes. On the other hand we are also utilizing additive manufacturing for

producing standard components in volume such as the bracket for an alarm system or the hinge mechanism for the swing-out shower stall”.

A challenging post processing task

To date the de-powdering and cleaning of PA 12 components, produced by a powder-bed printing system, was done manually in a blast cabinet. Since this post processing operation required not only a lot of labor and time but also produced highly erratic and inconsistent results, the company was looking for an automated alternative.

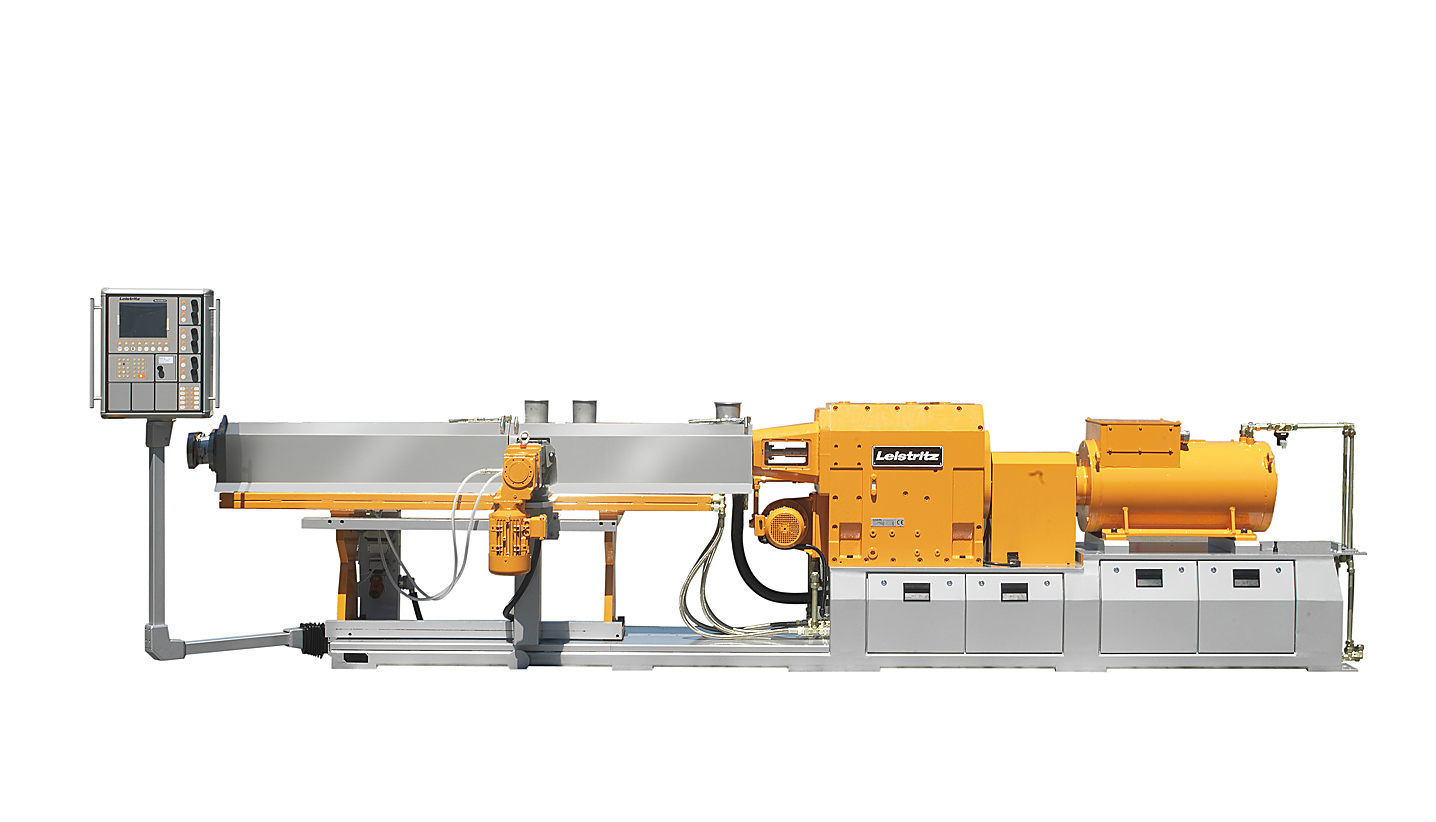

Therefore, comprehensive processing trials were run with different components in the Customer Experience Center of AM Solutions – 3D post processing technology. This division of the Rösler group specializes in post processing solutions for 3D printed components. After conclusion of the highly successful processing trials the customer chose

the S1 shot blasting system. This shot blast machine was specifically developed for the post processing of plastic

components produced with the powder bed printing method. The plug and play S1 is the

only machine on the market that allows the time-saving and cost-efficient de-powdering asn well as surface smoothing and homogenization of 3D printed components in one single machine. All that is required, is a simple change of the blast media, for example, from glass beads to plastic spheres. The S1, equipped with a basket that rotates during the finishing operation and allows easy, ergonomic loading and unloading of the work pieces, allows fully automatic batch

processing. Throughout the entire process the basket remains in the machine housing. This, combined with a special door sealing system, prevents any powder spillage into the immediate surroundings. The control panel allows an easy and quick switch to manual operation without any retooling. „More and more companies from different industries are

choosing the S1 for post processing of their 3D printed components. This is a confirmation for our product strategy. It shows that our 3D post processing products are in full compliance with the requirements of the market”, adds Manuel Laux, Head of AM Solutions – 3D post processing technology.

Perfect cleaning results and quick amortization

Mario Meszaros comments: „The fact that after surprisingly short cycle times the components came out of the machine perfectly clean and without any powder residues was very impressive”. He continues: „With the underlying operating data I prepared a ROI calculation. The results quickly convinced our management: Even with only three print jobs

per week in the S1, we already achieve a return on investment after roughly two years. However, it is safe to assume that the quantity of 3D printed components will increase significantly. This will drastically reduce the amortization period.”

High process stability and operational safety

The benefits of the S1 are not only limited to the excellent processing results and the quick amortization. In its standard version it also features a system that automatically monitors and records all relevant process parameters. The integrated blast media cleaning and recycling system represents another reason for the high process stability. It ensures that irrespective of the media type the media is always available in perfect condition. Another

plus is the explosion protected design of the shot blast machine with ATEX compliant motors

and valves. Mario Meszaros concludes: „I am absolutely convinced that the simple, effective

and efficient post processing possibilities of the S1 will further promote the use of additive

manufacturing in our company”.

www.solutions-for-am.com.

Underline: The plug and play S1 is the only machine on the market that allows the timesaving and cost-efficient de-powdering as well as surface smoothing and homogenization

of 3D printed components in one single machine. All that is required, is a simple change of

the blast media, for example, from glass beads to plastic spheres.

Underline: On the one hand, Knaus Tabbert uses 3D printing to produce prototypes. On the

other hand, this technology is also used to produce series components, such as a bracket

for an alarm system or the hinge mechanism of the swing-out shower cabin. An S1 system

from AM Solutions – 3D post processing technology is utilized for the post processing

Underline: „My amortization calculation has shown that the post processing of only three

print jobs per week results in a return on investment of the S1 after about two years”,

comments Mario Meszaros, development engineer at Knaus Tabbert.

For over 80 years, the privately owned Rösler Oberflächentechnik GmbH has been actively engaged in the field of surface preparation and surface finishing. As global market leader, we offer a comprehensive portfolio of equipment, consumables and services around the mass finishing and shot blasting technologies for a wide spectrum of different industries. Our range of about 15,000 consumables, developed in our Customer Experience Centers and laboratories located all over the world, specifically serves our customers for resolving their individual finishing needs. Under the brand name AM Solutions, we offer numerous equipment solutions and services in the area of additive manufacturing/3D printing. Lastbut-not-least, as our central training center the Rösler Academy offers practical, hands-on seminars to the subjects mass finishing and shot blasting, lean management and additive manufacturing. Besides the German manufacturing locations in Untermerzbach/Memmelsdorf and Bad Staffelstein/Hausen the Rösler group has a global

network of 15 locations and 150 sales agents. For more information, please go to: www.rosler.com

Knaus Tabbert AG

Headquartered in Jandelsbrunn, Bavaria, the Knaus Tabbert AG is a leading manufacturer of recreational vehicles. Other company locations are Mottgers and Schlüsselfeld in Germany and Nagyoroszi in Hungary. Since September 2020 the company is listed at the Frankfurt stock exchange in the segment prime standard (ISIN: DE000A2YN504). In 2020

the Knaus Tabbert AG, with its brands KNAUS, TABBERT, T@B, WEINSBERG, MORELO and the internet platform RENT AND TRAVEL, achieved a sales volume of around 800 million Euros and, with about 3,000 employees, manufactured more than 24,000 recreational vehicles. Please find more information under: www.knaustabbert.de

Contact information for the editors:

SCHULZ.PRESSE.TEXT., Doris Schulz, Journalistin (DJV), Landhausstraße 12, 70825

Korntal, Telefon +49 711 854085, [email protected], www.schulzpressetext.de

Rösler Oberflächentechnik GmbH, Daniel Hund, Vorstadt 1,

96190 Untermerzbach, Phone +49 9533 924802, [email protected], www.rosler.com