Geneva, October 2012. Through material science-driven innovation DuPont expands its Zytel® long-chain polyamide portfolio with new grades that deliver flexibility and salt stress cracking resistance similar to PA11 and PA12.

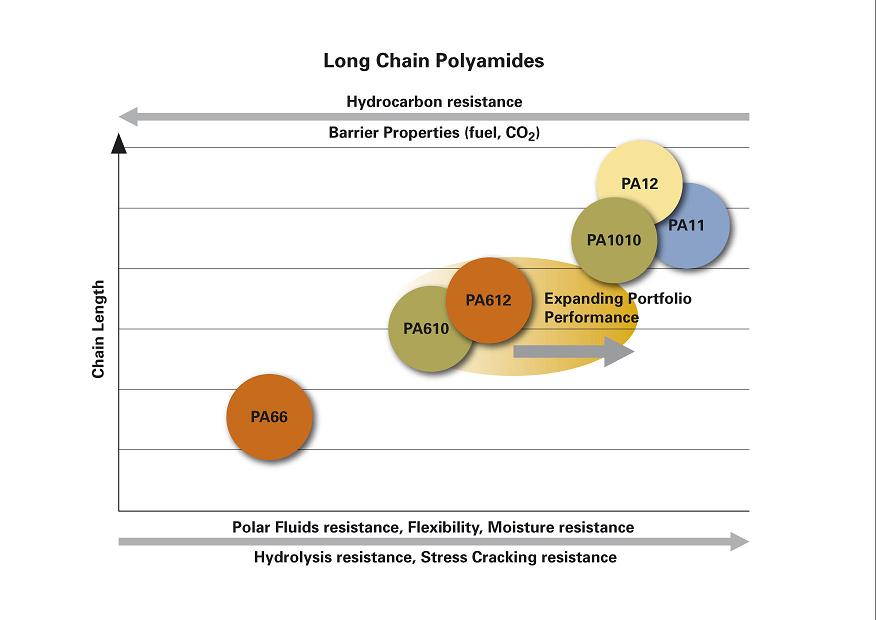

The two new series, Zytel® LC 7000 and Zytel® RS LC 4000 – already commercially established – exploit a new polymer backbone, extensively modified from that used in PA 612 and the renewably sourced PA 610. The result is two high-performance specialty polyamides, which offer functional attributes that make them suitable for use into automotive and commercial vehicle applications, including fuel and air brake lines – typically the domain of PA12.

H. Chul Lee, Global LCPA program manager, at DuPont Performance Polymers said: “Test bars made of Zytel® RS LCPA, PA11 and PA12 were exposed to a 50 percent zinc chloride solution for one week and then bent to the point of break. The PA11 and PA12 samples broke before the Zytel® samples showed signs of stress cracking; these are the kinds of capabilities that make them suitable for use in place of PA11 and PA 12.” The two new series also offer low permeability, an excellent yield stress/stiffness balance and a broad extrusion processing window, with blow molding also being a possibility. In comparison to existing market grades, they offer flexibility similar to PA12 but with significantly better cold impact toughness.

Due to their enhanced chemistry, they are suitable for tie-layer free adhesion to a variety of polymer classes including PA 6, functionalized polyolefins and even Ethylene Vinyl Alcohol (EVOH). They are thus well suited for multi-layer constructions. “These new series can lower the overall system cost versus incumbent materials,” said Mario Delbosco, global automotive marketing manager, LCPA, at DuPont Performance Polymers. “They provide a commercially and functionally viable alternative to PA12s, which have recently been beset with supply issues. What is more, with PA12 sometimes being an over-engineered option for many applications, these two new series offer a much better fit… across a great many industries.”

Targeted uses include: fuel lines, truck air brake tubes, industrial pneumatic tubing, vacuum brake tubes (automotive), air brake coils (trucking), coolant hoses/pipes, venting tubes and metal brake line coatings. With these types of applications in mind, Zytel® RS LC 4000 and Zytel® LC 7000 series are compliant to ISO 7628 and SAE J844 for Air Brake Tubing and SAE J2260 for fuel lines. DuPont offers more than 100 materials and product families for the global automotive industry. Through its global application development network, DuPont Automotive is committed to collaborating with customers throughout the value chain to develop new products, materials, components and systems that help reduce dependence on fossil fuels and protect people and the environment. For more information, visit automotive.dupont.com.

DuPont Performance Polymers is committed to working with customers throughout the world to develop new products, components and systems that help reduce dependence on fossil fuels and protect people and the environment. With more than 40 manufacturing, development and research centers throughout the world, DuPont Performance Polymers uses the industry’s broadest portfolio of plastics, elastomers, renewably sourced polymers, filaments and high-performance parts and shapes to deliver cost-effective solutions to customers in aerospace, automotive, consumer, electrical, electronic, industrial, sporting goods and other diversified industries.

DuPont (NYSE: DD) has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since 1802. The company believes that by collaborating with customers, governments, NGOs, and thought leaders we can help find solutions to such global challenges as providing enough healthy food for people everywhere, decreasing dependence on fossil fuels, and protecting life and the environment. For additional information about DuPont and its commitment to inclusive innovation, please visit www.dupont.com.