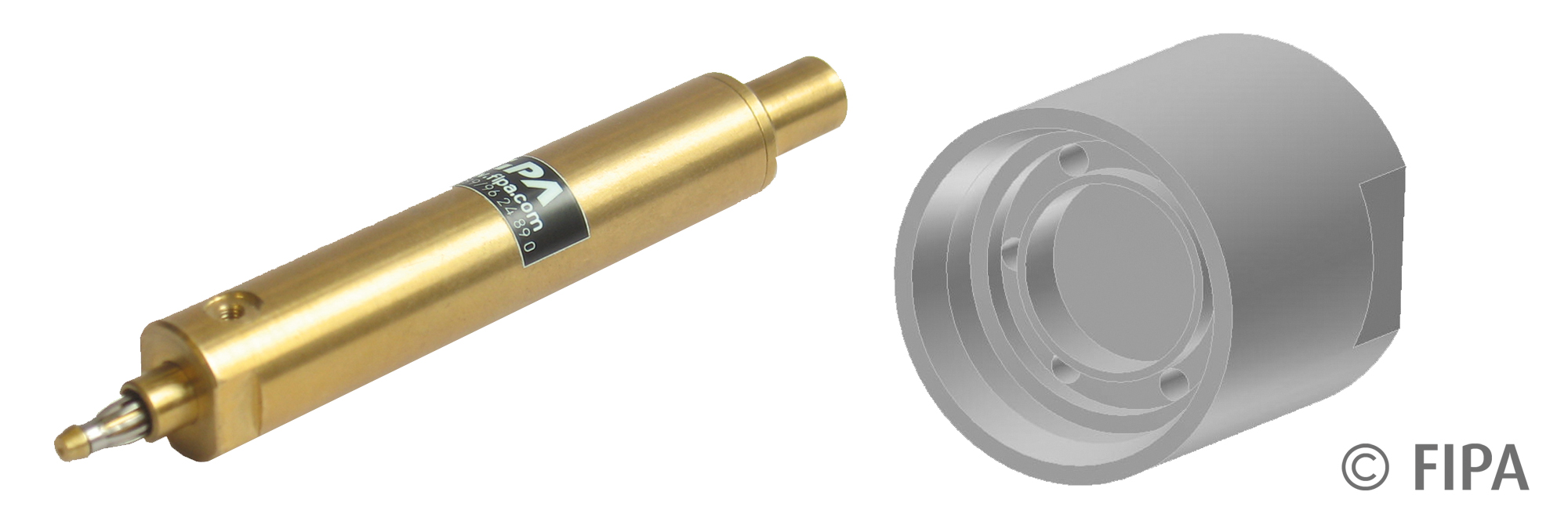

Individual design, compact structure and simple gripper integration: FIPA GmbH (www.fipa.com) has expanded its program to include a customised insert-gripper for handling inserts in plastic injection-moulded parts. FIPA offers a solution tailored to individual requirements, which is even economically feasible from batch size 1. The user can choose between vacuum- and air-powered grippers. FIPA insert-grippers are used in domains including automobile, pharmaceuticals and electronics.

FIPA insert-grippers are gripping devices used to handle inserts securely. These grippers are precisely tailored to the geometry of the material to be handled and guarantee optimal process security, even with high cycle times. Both vacuum- and air-powered versions are available, adapted to the respective application. This means, for example, nuts or threaded connections can be securely gripped on the face side using a vacuum, where the use of an internal/external gripper would not be possible.

Here, the suction surface corresponds to the negative profile of the work piece. On the other side, the air-powered gripper can, for example, securely grip threaded bushings from inside and insert into an injection-moulded tool. Available housing materials include either a high-strength aluminium alloy or a polyamide-based high-performance plastic.

These plastics are designed to be safe for foodstuffs, very light and thus ideal for high dynamics. A further boost is the fact that media ducts for compressed air or vacuum can be integrated into the gripper, which helps minimize the hose connection effort and space requirements. An innovative manufacturing method means this gripper can be manufactured cost-effectively, even from batch size 1.

FIPA insert-gripper at a glance:

- Precise adjustment to component geometry: Secure handling with high cycle times.

- Freely selectable media: Highly flexible applications, with air-powered or vacuum control as desired.

- Flexible material selection: High-strength aluminium alloy or high-performance plastic designed for use with foodstuffs.

- Easy integration into gripper systems: The insert-grippers are compatible with the FIPA modular system and also compatible with third party systems.

- Economic production: Even from batch size 1, can be deployed swiftly and efficiently.

- Quick exchange: With quick-action couplings, gripper heads can be replaced without having to dismantle the entire gripper system.

Competent solution supplier for the material flow

Leveraging its many years of experience, FIPA also plans and builds complete gripper systems. All from a single source and based on the principle of the modular gripper kit, which allows individual solutions. Naturally, the new customised gripper tools can also be integrated into existing gripper constructions.