- Technical treats

- Highlight: production of light-guide panels

- LSR dummies for babies

Lossburg. The Taipei Plas takes place every two years in the Taipei World Trade Center Nangang Exhibition Hall. As a plastics technology showcase for company representatives and industry experts, predominantly from Asia, Arburg will use this year’s exhibition for the presentation of two high-end applications running on hydraulic Allrounder S machines. The event will be held from 21 to 25 September. The Arburg exhibition stand will be located in Hall 1F, Stand I0108.

With both of these machines, the company will clearly demonstrate that the S series, with its modular technical equipment, which is adaptable to every requirement, covers a very wide-ranging production spectrum.

Highlight: light-guide panels

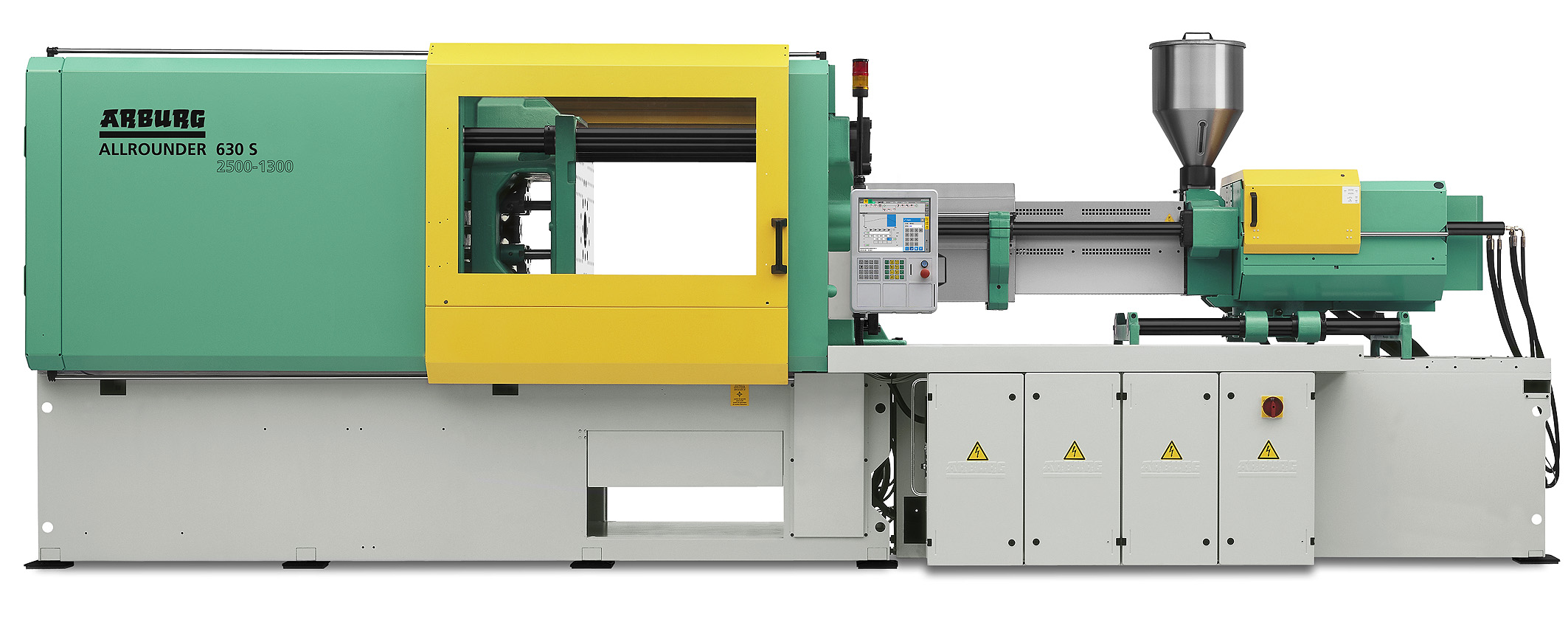

The production of light-guide panels on an Allrounder 630 S with a clamping force of 2,500 kN and a size 1300 injection unit, is well suited to the Asian region with its numerous manufacturers of PC and media technology. The light-guide panels for energy-saving TFT screens with LED background illumination are produced in a two-cavity mould. The necessary high luminous efficiency requires the thinnest possible components with a corresponding optical surface structure. The injection moulding process is therefore combined with compression injection moulding on this machine.

The light-guide panels have a thickness of 0.5 mm and a demanding flow/path wall thickness ratio of 350:1 The cycle time is around 15 seconds, whereby the compression moulding process with an injection time of approx. 50 milliseconds takes place highly dynamically and simultaneously with injection. The Allrounder 630 S is equipped with hydraulic accumulator technology, position-regulated screw and electro-mechanical dosage drive; it consequently bears the Arburg “e²” energy-efficiency label. Moulded part transport is performed by a horizontally-operating Multilift H robotic system, which is fully integrated in the Selogica control system.

Dummies for babies made from LSR

Due to its foodstuff compatibility, suitability for use in the health sector, durability and robustness, liquid silicone (LSR) is used for the high-volume production of babies’ dummies. The dummies are produced in an eight-cavity mould on an Allrounder 370 S with a clamping force of 700 kN, size 290 injection unit and appropriate LSR equipment. The moulded part weight is 5 grams and the cycle time is 30 seconds. Preparation of the two-component material is performed by an LSR dosage and mixing unit from 2KM.

With the two exhibits, Arburg will clearly demonstrate that efficient moulded part production is not only achievable with electric or hybrid machines. The modular and thus universal hydraulic S-series Allrounders are perfectly adapted to the individual product requirements and operate to a high quality standard at low unit costs.