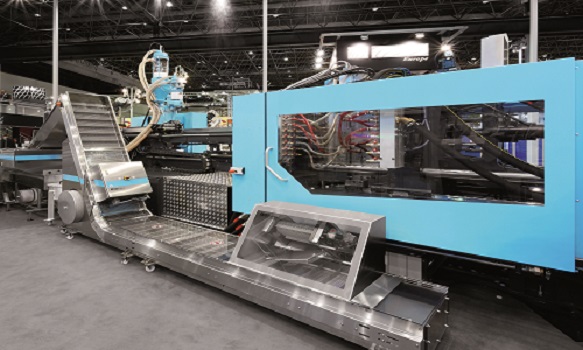

Groche Technik GmbH, based in Kalletal, Germany, has made a name for itself across Europe over more than 40 years as manufacturer of bespoke and standard high-quality/high-performance plasticizing screws and barrels for injection moulding and extrusion technologies. Today, the company’s products portfolio encompasses several hundred types of screws and designs. Diameters vary from 10mm to more than 200mm at lengths of up to 4,500mm. Managing director Armin Groche and his team at FAKUMA will present – as the highlight – the so-called ‘Long-life Screw’, together with some 75 other exhibits. The ‘Long-life Screw’ has been developed and is manufactured in-house. New to the portfolio this year is the product and service programme of Extreme Coatings. Last, but not least, prospective buyers and visitors to the Groche Stand 7114 in Hall A7 can obtain information about trail-blazing new developments, such as the direct long-fibre injection moulding technology with EFE single-screw fibre feed-in. Here, the retention of the material structure of long-fibrous reinforcement materials is ensured, as far as it is possible, together with their component-improving fibre orientation.

Longlife-Screw

With new screw coatings of a degree of hardness of up to 68-71 HRC (Hardness Rockwell), plasticizing extremely complex plastics does not pose any problems. These screws are used, for example, with polymers containing glass fibre or other highly aggressive materials in the metal or ceramics moulding sectors – in conjunction with high-wear and corrosion resistant bimetal cylinders. “We have established statistics to show that our screws have reached double the service life compared with those with powder metallurgical materials. In line with that, the maintenance intervals will be further apart. In addition, users can make economies with regard to disassembly, cleaning and installation. Availability is very high, the production flow has improved sustainably“, emphasises Armin Groche.

Europe-wide distribution of Extreme Coatings products and services

With effect from June 1, 2012, Extreme Coatings, the Florida-based experts for coating screws to the highest possible degree of indestructibility, has transferred the exclusive distribution rights for Europe to Groche Technik GmbH. This ensures the direct supply of tungsten and chromium carbide screws for aggressive injection moulding and extrusion applications. The applied thermal injection method (arc spray method), using hard metals such as carbide, can double or improve five-fold the life of components. A diamond polishing method, developed in-house, gives the screw the desired high-gloss finish.

Direct long-fibre injection moulding technology

In direct long-fibre injection moulding, including EFE single-screw fibre feed-in, strands of fibres can be fed into the melt. The fibres are brought to equal length in a controlled way. Here, the melt acts as lubricant and ensures that the long fibres fulfil their task unbroken and targeted within the product. With this new technique, not only is compounding eliminated, it also results in impressive technological (and thus cost-specific) advantages within the component, such as improvement of the mechanical characteristics, much improved stiffness, better strength, impact strength and cryogenic resistance, among many others. All will be revealed to visitors at FAKUMA.