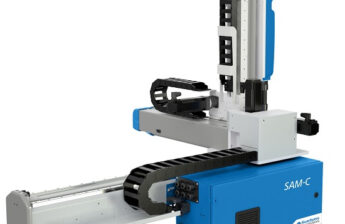

Thriam Toolroom, a leading name in precision tooling and plastic products manufacturing, has taken a significant leap forward in its production capabilities by installing a Haitian 300-ton injection moulding machine at its Ahilyanagar facility. This strategic addition marks a significant milestone in Thriam’s journey to support larger, more complex projects with enhanced efficiency, precision, and quality assurance. As customer requirements evolve and demand for high-performance plastic components increases, Thriam is fully geared to deliver world-class solutions.

“With the growing expectations from our customers and the evolving demands of the industry, we are committed to bringing the best out of our toolroom,” said Minu Madhukumar, CEO of Thriam Toolroom. “We were greatly encouraged by the appreciation we received during the opening of our new facility in November 2024. Staying true to our commitment to strengthening the manufacturing ecosystem, adding the Haitian 300 Ton machine is another step forward in expanding our capabilities and setting new benchmarks.”

Thriam Tool Room, a leading precision engineering enterprise under the Thriam Group, offers advanced tooling and component manufacturing in India. With over three decades of engineering expertise backing its journey, the company has carved a niche in designing and delivering high-precision tooling solutions across critical sectors such as automotive, aerospace, medical devices, electronics, and consumer goods. Known for its commitment to innovation, reliability, and customer-centricity, Thriam Tool Room serves global manufacturers seeking performance, precision, and perfection.

“Our core strength lies in its world-class infrastructure and a team of experienced engineers who bring together innovation and execution. Our capabilities span the complete lifecycle of tooling solutions – from conceptual design to final validation”, added Minu. The facility is equipped with advanced CAD/CAM software, high-speed CNC machining centers, EDMs, and CMM inspection systems, enabling them to manufacture complex molds, dies, jigs, fixtures, and precision components with micron-level accuracy. Thriam’s expertise also extends to prototyping and small batch production, ensuring rapid turnaround and flexibility for customers.

The latest investment builds on Thriam Toolroom’s existing infrastructure, which includes machines ranging from 80-ton to 200-ton capacities. This allows the company to serve various industries, including automotive, consumer electronics, medical devices, and more. As industries demand visually refined and technically complex plastic components, Thriam’s enhanced capabilities with the new 300-ton machine empower it to meet high-volume production needs with greater precision.

Driven by a vision to enable manufacturing excellence, Thriam Tool Room has consistently invested in upgrading its technologies, skills, and systems to meet the evolving demands of global markets. Founded in 1989 by Madhukumar, Thriam Toolroom offers mold manufacturing, injection moulding, compression moulding, and 3D printing. It helps customers confidently build, develop, and scale their plastic products.

Source: themachinemaker.com