Syensqo, a spin-off from chemicals company Solvay, has unveiled its first grade of extrudable polyphenylene sulfide (PPS) for piping applications.

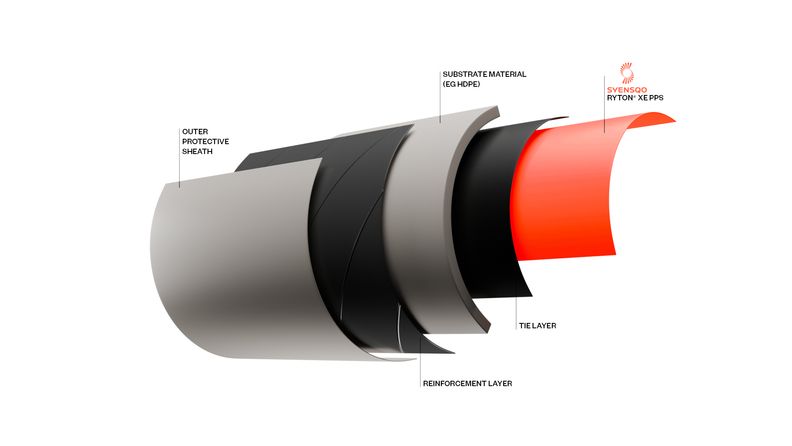

The Ryton PPS XE-5000 material improves the durability, sustainability, and efficiency of piping systems used in high-demand applications. It is ideal for use in inner liners, stand-alone, and composite pipes commonly used in the oil and gas and other energy applications.

“There is a growing need for new piping materials solutions capable of exceeding the chemical, thermal, and pressure resistance of conventional polyethylene or polyamide resins without compromising processability or efficiency,” said William Sattich, principal scientist for PPS at Syensqo.

“In addition to meeting these requirements, our advanced Ryton PPS XE-5000 technology delivers high-performance extrudable thermoplastic compounds with a permeation resistance far superior to that of common piping materials, revolutionising the energy industry’s approach for piping solutions,” he added.

Syensqo’s Ryton portfolio is widely used in automotive, electrical, electronics, and appliances applications, meeting especially high thermal and mechanical performance requirements. The material can replace metal and thermosets whilst also reducing fuel consumption and overall costs.

At its Kallo-Beveren PPS compounding site in Belgium, Syensqo’s operations run on 100% renewable energy, which covers the complete decarbonisation of the plant regarding direct (Scope 1) and indirect (Scope 2) emissions under the Greenhouse Gas (GHG) Protocol.

The use of renewable energy in compounding also reduces the overall carbon footprint of Ryton PPS compounds.

At Fakuma, Syensqo will showcase a range of materials for high-voltage battery applications and e-mobility electrical components, including grades from the Ryton portfolio.

Building on last year’s Fakuma launch, Syensqo will continue to expand its Echo portfolio of high-performance solutions incorporating bio-based, recycled, and mass balance certified raw materials.

At Fakuma’s Exhibitors’ Forum, Syensqo will further underscore its materials and market expertise. Visitors are invited to join a live presentation by Ysée Genot, E-Mobility & Sustainability Marketing Manager, and Ricardo Calumby, Construction & Sustainability Marketing Manager, on Oct. 18 at 09:40 CET in Room Berlin, where they will present Top-Notch Circular Polymers: Experience Uncompromised Performance with Syensqo.

Source: sustainableplastics.com