Braskem and Weav3D, in partnership with the Clemson Composites Center at Clemson University, have been named first place winners of the 2024 Altair Enlighten Award’s Future of Lightweighting category. Awarded annually, the Altair Enlighten Award honours the greatest sustainability and lightweighting advancements that successfully reduce carbon footprint, mitigate water and energy consumption, and leverage material reuse and recycling efforts. The award is a joint initiative with the Center for Automotive Research (CAR) and was presented this year on August 6, 2024, at the CAR Management Briefing Seminars.

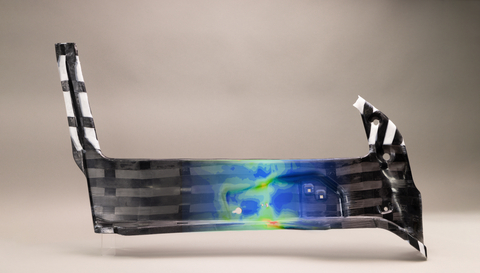

The partnership was recognised for the cost-effective lightweight solution it developed to enhance the performance of PP for structural automotive applications. The solution, an industry-first high-rate structural automotive prototype using Weav3D’s tunable woven composite technology and Braskem’s cost-effective PP resin, drew on Clemson Composites Center’s extensive experience in stamp-forming thermoplastic composites, gained from the US Department of Energy’s Ultra-Lightweight Door programme, said Sai Aditya Pradeep, former Manufacturing Applications Engineer and Project Lead for Clemson.

The combination of WEAV3D composite lattice reinforcement with Braskem PP enables lighter and less expensive thermoplastic solutions than conventional organosheet. The patent-pending WEAV3D composite forming process enables the production of optimized lattice structures that can be combined with injection molding or thermoforming processes to create lightweight structural composite parts at a fraction of the cost and cycle time associated with traditional composite manufacturing.

“The partnership …combined to create a truly innovative material that provides for more sustainable lightweight solution to help reduce vehicle carbon emissions all while enhancing manufacturing process value through material cost savings,” according to Joel Carr, Technical Service and Development Engineering Team Leader, Braskem America. “This is a win-win for our clients and the planet.”

Compared to conventional composite organosheet, Weav3D’s

Rebar for Plastics and Braskem PP offers multiple benefits. It reduces sheet blank weight by ~50% and final part weight by ~23%; lowers costs by ~50%; and increases sheet yield from 25% to 45% by weight, resulting in a 62% reduction in trim waste.

As Christopher Oberste, President and Chief Engineer of Weav3D, pointed out: “Using the right material in the right place keeps cost and waste low, while still delivering substantial weight savings and performance benefits to our automotive customers.”

Source: sustainableplastics.com