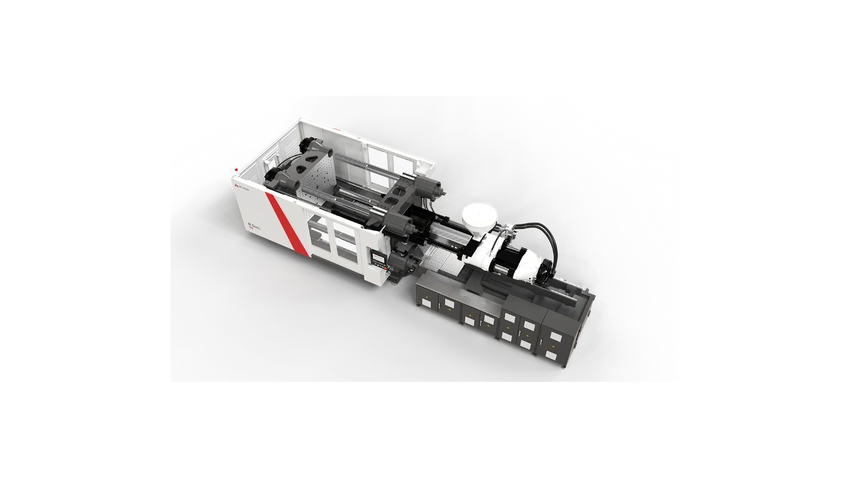

Milacron’s M-Series injection molding machine (IMM) platform will make its North American debut at NPE2024, featuring in two applications at the Ohio-based company’s booth from May 6 to 10 in Orlando, FL.

The M-Series features as standard the largest clamp stroke in the mid-tonnage hybrid range, the company said. Fanuc motors and drives power the platform, which is based on two-platen technology and can be integrated with multiple co-injection technologies to support customer sustainability requirements.

This video provides a brief introduction to the M-Series features.

Two applications showcasing the M-Series are planned at the company’s booth:

- A two-cavity mold-pail application with up to 50% recycled core and in-mold labeling automation performed by the M-1070 using Mold-Masters co-injection technology.

- Custom textures and backlighting for automotive and appliance applications using an M-500 machine cell featuring a Mold-Masters hot runner and Kurz in-mold decoration technology.

Available from 500 to 1,250 tons, the M-Series also features:

- Moving platens on LM guides on the clamp end, with standard power-operated gates and chrome-plated strain rods.

- Increased maximum mold weights, improved dry-cycle times, and supported strain rods in the mold section.

- Twin-cylinder injection units for equal distribution across the screw.

- Injection swivel for easy screw removal.

- Insulated heater bands.

- Linear position transducers for accurate injection position control.

- A 21.5-inch touch screen control panel with swing arm to improve viewing of the mold area. The panel’s “plus” section enables configurable screen viewing; 8+8 configurable I/Os is standard.

Besides its M-Series, Milacron will also be spotlighting the following:

- Q-Series platform, a low- to mid-tonnage range featuring double-toggle design and servo-hydraulic operation for fast production using less energy. A Q-170 machine with G3 Mosaic control and DME mold technology using bio-resin will be featured in a mobile phone holder application.

- All-electric Fanuc Roboshot in two applications. The Robo 55, using liquid silicone rubber material and automation, will be in a cell featuring a micro plunger to control a tiny shot for an umbrella part. The Robo 275 will demonstrate a 48-cavity medical vial application using Milacron’s stainless steel water system and new M3 thermocouple technology from Mold-Masters.

- SG75 extrusion system with a new control, new die heads, and advanced single/twin screws and barrels. The package includes all downstream equipment — vacuum tank, pullers, saws, and more. A cobot at the end of the line will perform demonstrations.

- M-Powered IIoT remote digital solution that uses built-in analytics of real-time machine data to identify causes of downtime, production inefficiencies, and quality issues.

- L-Series low-pressure injection molding machinery, capable of running up to 100% regrind flake material. The machine will not be on site but featured in an animation loop.

Source: plasticstoday.com