DarWIN research project accelerates multi–manufacturer

machine learning

Collaborative programme between plus10, SKZ and Sumitomo (SHI) Demag identifies AI

advances and how injection moulding machines from multiple manufacturers can learn from each

other.

Schwaig, January 2022 – The Fraunhofer spin–off plus10 has been conducting application–oriented

research together with the South German Plastics Center SKZ. As part of their DarWIN research

project, new AI–based process optimisation tools have been developed specifically targeting

injection moulding machines. Sumitomo (SHI) Demag was selected to perform the final series of

comprehensive research tests.

A beacon for automated machine learning in the future, the ambitious project has focused on developing

continuous learning models that deliver higher moulding quality in shorter cycle times, around the clock. To

accomplish this overarching strategy and facilitate autonomous reactions to individual production situations,

the research team has captured valuable deep learning from different machinery manufacturers.

An R&D program instigated in the mid-2020s, developments accelerated at speed in 2021 with a series of

machine learning tests facilitated by the Fraunhofer spin-off plus10 and the SKZ plastics centre. Labelled

the DarWIN research project, this AI program focused specifically on gathering detailed and transferrable

processing behaviours from multiple models of injection moulding machines using high-frequency machine

data.

Through the transferability of pre-trained machine learning models, the DarWIN project proves that

individual machines from different manufacturers have the capability to learn from each other. In reality,

this now means that individual behavioural models of a specific machine don’t have to be completely relearned every time. Instead they can be adapted to the machine and product application through minor

automated adjustments.

This ability to adapt to the prevailing conditions, for example raw material characteristics and ambient

conditions, provides robust evidence that processing patterns and behavioural models are transferable to

machines of similar size and technology, regardless of the manufacturer.

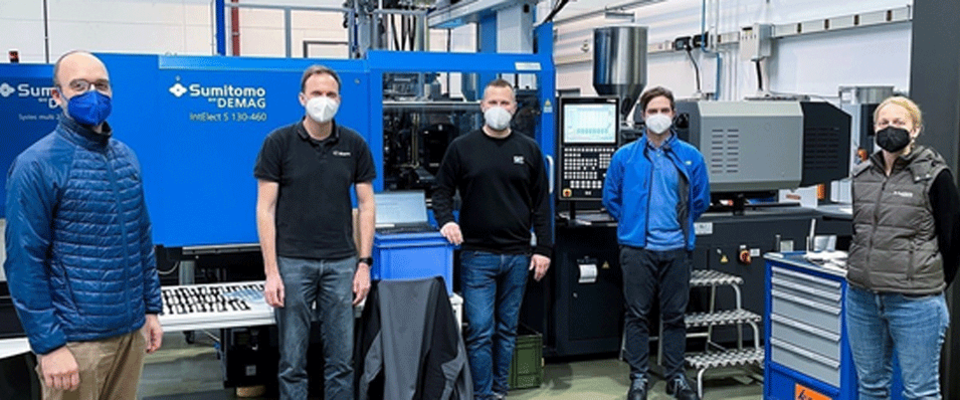

AI tests performed on Sumitomo (SHI) Demag machines

Most recently, plus10 and the SKZ performed a series of thorough AI pilot tests on Sumitomo (SHI) Demag

machines. Thanks to the high-frequency machine connectivity, Sumitomo (SHI) Demag machines provide

the ideal platform to put the plus10 algorithms through their paces.

Offering real-time communication in the millisecond range, the company’s advanced machine controllers

are ‘AI-ready’. This universally compatible digital interface allows for seamless communication across all

machinery assets. Additionally, it facilitates easy implementation of continuous learning AI-based

optimisation tools. Accomplishing optimal productivity at all times and allowing for further advances in

interface design, continuous learning and AI-based software developments.

By providing this real test environment, Sumitomo (SHI) Demag continues to demonstrate how the company

is proactively addressing the innovations coming down the line, delivering intelligent automation and

actively shaping the future of injection moulding.

Supporting sustainable plastics production

The test simulation results further underpin the strong industry emphasis placed on sustainable plastics

processing. Specifically, the plus10 technology allows for stable processing of sensitive and heterogeneous

materials, such as thermoplastic post-consumer recyclables and fast-curing elastomers. Thus supporting

all the efficiency and defining characteristics of a fully circular plastics processing economy.

The research project ‘DarWIN’ was funded by the Federal Ministry of Education and Research (BMBF

funding code 01IS20066). Concluding on 31 December 2021, the results are currently being processed

and incorporated into the plus10 software. Plans are in place to publish the detailed insight at the end of

2022. Additional activities and live demonstrations of the development results will be shared at specialist

events, including the “Digital Injection Moulding Meeting” to be hosted at the SKZ in Würzburg.

Contact

Alexandra Schaper

Marketing Manager

Sumitomo (SHI) Demag

+34 674 365 956

mailto:[email protected]

Sumitomo (SHI) Demag Plastics Machinery GmbH

Sumitomo (SHI) Demag has shaped the development of the plastics industry from its very beginning. As a

specialist for injection moulding machines for plastics processing, Sumitomo (SHI) Demag and its Japanese

parent company are leading the industry.

The global development and production network of Sumitomo Heavy Industries and Sumitomo (SHI)

Demag is comprised of four facilities in Japan, Germany and China with more than 3,000 employees. The

product portfolio includes all-electric, hydraulic and hybrid injection moulding machines with clamping forces

of between 500 and 15,000 kN. With more than 149,000 installed machines, Sumitomo (SHI) Demag is

present in important global markets and ranks among the largest manufacturers of injection moulding

machines in the world.

At Sumitomo’s headquarters in Chiba, Japan, the company manufactures machines with clamping forces

in the small to medium range. Nearly 95 % of all delivered machines are equipped with an all-electric drive

concept. Sumitomo (SHI) Demag’s German facilities in Schwaig and Wiehe produce the Systec Servo

range with hybrid drive as well as the El-Exis SP and Systec SP range of high-speed, high-performance

machines. The all-electric IntElect range for international customers is also being produced in Germany.

As early as 1998, Sumitomo (SHI) Demag set up its first production site in Ningbo/China. In 2015, the

Chinese subsidiary Demag Plastics Machinery (Ningbo) Co., Ltd. installed a new facility with a 13,000 m²

floor space. It is earmarked for the production of the Systec C range with clamping forces of between 500

and 10,000 kN for the Asian market.

In addition to injection moulding machines, Sumitomo (SHI) Demag offers customised and standardised

systems for the part handling automation, technical and process solutions for special applications, tailored

services and service concepts as well as a range of financial options to support investment in injection

moulding machines.

With its comprehensive sales and service network of subsidiaries and agencies, Sumitomo (SHI) Demag

is present in all major markets.

About plus10

plus10 GmbH is a Fraunhofer AI spin-off for automated production optimization with locations in Augsburg

and Stuttgart. The company specialises in developing continuous learning and situation-based optimisation

software, specifically for fully automated complex machines and systems within all industries, notably GMPcompliant tools for the pharmaceutical and medtech sectors. The AI algorithms reduce short stops,

malfunctions, chain losses, quality rejects as well as fault search time in large plants and recommend

process adjustments to parameters, for example. By doing so, productivity and system effectiveness are

significantly increased, rejects are avoided and a range of output issues are minimised.

Further information about plus10:

Felix Georg Müller

E-Mail: [email protected]

Tel. +49 821 7898 6400

Website: https://plus10.de

LinkedIn: plus10